Researchers from MIT have fabricated a functional dialysis membrane from a sheet of graphene. The team’s membrane is able to filter out nanometer-sized molecules from aqueous solutions up to 10 times faster than state-of-the-art membranes, with the graphene itself being up to 100 times faster. The graphene membrane is also very thin; It's less than 1 nanometer thick, while the thinnest existing membranes are about 20 nanometers thick.

Dialysis can be generally described as the process by which molecules filter out of one solution by diffusing through a membrane, into a more dilute solution. The most recognizable form is hemodialysis, which removes waste from blood, but scientists also use dialysis for many other applications, like purifying drugs, removing residue from chemical solutions, and more, typically by allowing the materials to pass through a porous membrane.

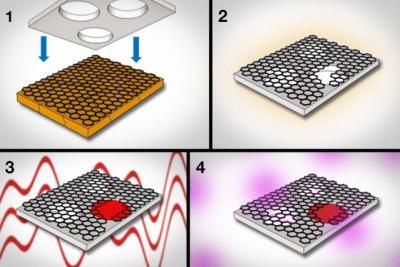

In order to make the graphene membrane, the researchers first used chemical vapor deposition to grow graphene on copper foil. They then carefully etched away the copper and transferred the graphene to a supporting sheet of polycarbonate, studded throughout with pores large enough to let through any molecules that have passed through the graphene. The polycarbonate acts as a scaffold, keeping the ultrathin graphene from curling up on itself.

The researchers aimed to turn graphene into a molecularly selective sieve, letting through only molecules of a certain size. To do so, they created tiny pores in the material by exposing the structure to oxygen plasma, a process by which oxygen, pumped into a plasma chamber, can etch away at materials. This allowed them to control the density and size of pores, in the areas where the graphene is pristine. The team found that the longer graphene is exposed to oxygen plasma, the larger and more dense the pores will be. Relatively short exposure times, of about 45 to 60 seconds, generate very small pores.

The team carried out selectivity experiments with the graphene membrane, as well as with commercial dialysis membranes, and found that, in comparison, the graphene membranes performed with higher permeance", filtering out the desired molecules up to 10 times faster.

To make the graphene membrane even better, the team plans to improve the polycarbonate support by etching more pores into the material to increase the membrane’s overall permeance. They are also working to further scale up the dimensions of the membrane, which currently measures 1 square centimeter. Further tuning the oxygen plasma process to create tailored pores will also improve a membrane’s performance â something that the team points out would have vastly different consequences for graphene in electronics applications.

What’s exciting is, what’s not great for the electronics field is actually perfect in this [membrane dialysis] field, the team says. In electronics, you want to minimize defects. Here you want to make defects of the right size. It goes to show the end use of the technology dictates what you want in the technology. That’s the key.