Skeleton Technologies is a developer and manufacturer of high energy and power density ultracapacitors. The company provides green and cost-effective energy storage solutions for the automotive, transportation, industrial and renewable energy markets.

Skeleton Technologies is a developer and manufacturer of high energy and power density ultracapacitors. The company provides green and cost-effective energy storage solutions for the automotive, transportation, industrial and renewable energy markets.

Skeleton Technologies SkelCap line of ultracapacitors are based on patented technologies of ultracapacitor design and advanced nanostructured carbon allowing for higher energy and power density than competitors. The company has devised a process that uses silicon carbide to make what they call "curved graphene".

Skeleton is reportedly working on increasing the manufacturing capacity for the Grossrhrsdorf production facility from half a million to about 1,000,000 supercapacitors per year in 2020. In terms of footprint, the current 3,500 square meters will be double to about 7,000 square meters by 2020.

Following the scale-up, the plan is to implement the next generation cell design, optimized for automated production and cell assembly. Further automation enables scaling up production capacity to 4,000,000 cells in the first phase, and ultimately to 10,000,000 supercapacitors to meet demand from automotive, grid, and transportation.

In 2020 Skeleton Technologies raised 41.3 Euro million ($48.5 million) in Series D financing round, bringing its total capital raised to over $109 million.

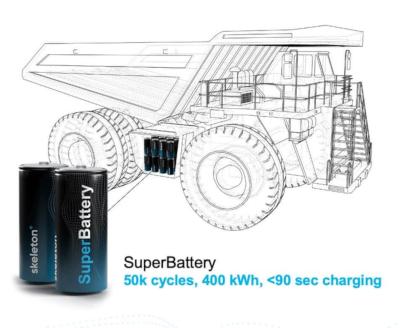

In September 2020 it was reported that Skeleton Technologies is developing a graphene-enhanced “SuperBatteryâ€, and that company signed a billion Euro letter of intent with a leading automotive manufacturer to bring the technology to market, most likely in 2023.

In August 2015, Skeleton entered the commercial truck fleet market when it launched a graphene-based device that helps truck drivers start their engines after long periods of inactivity or in cold weather. In July 2016, Skeleton Technologies announced that it will join French firm Flying Whales programme to build a 60-ton Large Capacity Airship, or LCA60T, for the global transport market. In 2020 Skeleton signed a large-scale contract with Medcom to deploy its supercapacitors for Warsaw's Tram network.

In 2019 Skeleton Technologies stated its plan to invest 25 million Euro in its plant located in the German state of Saxony. With this investment, Skeleton aims to expand its research and development as well as scale its production.

Gewerbepark Humboldtstraße Preuschwitzer Str. 20

02625 Bautzen

Germany

Skeleton Technologies secures €108 Million of financing from investors like Siemens and Marubeni

Skeleton Technologies recently closed a €108 million funding round that includes Siemens Financial Services (SFS), Marubeni Corporation and other investors. This funding will accelerate the development of next-generation products and finance the manufacturing expansion for supercapacitors and the company’s new high-power battery technology – the SuperBattery.

Skeleton Technologies’ CEO and Co-Founder, Taavi Madiberk, said: "Securing an investment from one of Europe's largest tech companies is a significant milestone for Skeleton. In addition to SFS’ investment, Siemens is also a key partner, supplier, and customer. Their expertise in industrialization and commercial partnerships will propel our growth and solidify our role in leading the energy transition”.

Skeleton & Martinrea to collaborate on batteries for refuse trucks

It was recently reported that Skeleton Technologies and the Canadian automotive supplier Martinrea International are cooperating to equip refuse collection vehicles for use in Paris and New York with Skeleton’s ‘SuperBattery’ technology.

Martinrea International develops and produces electric vehicle technologies for heavy-duty commercial vehicles through its subsidiary Effenco. The aim of the agreement with the Estonia-based Skeleton is to electrify fleets of refuse collection vehicles in Europe and North America, starting in New York City and Paris, and later to make the solution developed by both companies available worldwide. In autumn 2022, Shell had already become known as the first major customer for the graphene battery solution. Shell wants to use it to create electrification solutions for mining sites.

Skeleton Technologies launches its SuperBattery and unveils Shell as partner

Skeleton Technologies has officially launched its SuperBattery, and unveiled Shell as its partner. Skeleton is joining a Shell-led consortium to offer electrification solutions for mining sites.

SuperBattery is an innovative technology combining the characteristics of supercapacitors and batteries. SuperBattery has been developed to serve the needs of several sectors and is currently being used and/or tested in hybrid and fuel cell EVs, buses, trucks, and charging infrastructure.

Skeleton’s supercapacitors to power CAF’s new metro units in Granada, Spain

Skeleton Technologies has announced that it will supply its 'curved graphene'-enhanced supercapacitors to the metro units that Spanish manufacturer CAF will provide to the city of Granada, Spain.

Headquartered in Donostia - San Sebastian (Spain), the CAF Power & Automation has been working with Skeleton Technologies since last year. Following a successful tender, the Spanish manufacturer has been selected by the Metro de Granada to supply 8 new units for the city's network, which will be added to the 15 previously-delivered units which are

currently in service.

Skeleton Technologies announces new supercapacitor plant near Leipzig

Estonia-based Skeleton Technologies has announced that it is building Europe’s largest supercapacitor production facility in Saxony with the support of Siemens. Skeleton Technologies is investing 220 million euros in the new production facility in Markranstädt, near Leipzig in Saxony.

According to the company, 100 million euros will be invested in production and 120 million euros in development and research as well as in a future ramp-up of production. In the future, 12 million supercapacitors are to be manufactured annually in Markranstädt. The start of production is planned for 2024.

Skeleton Technologies announces agreement with ZPUE to provide supercapacitors to the Polish market

Skeleton Technologies and ZPUE, the largest manufacturer of electrical devices for electrical power distribution utilities in Poland, have entered into a commercial agreement to provide energy storage solutions to the Polish market.

The two companies signed a Letter of Intent under which Skeleton should supply supercapacitors for rail wayside storage at 200 MW per year from 2023 to 2025.

Skeleton Technologies closes €37.6 million D3 financing round

Skeleton Technologies has announced its Round D3 with 37.6 million euros of equity investments. The Round was led by Taavet Hinrikus, from Taavet+Sten with Nidoco AB, EIT Innoenergy, Bengt Wahlqvist, co-founder of battery charging specialist CTEK, a group of founding team members of Adyen and others joining.

The investments will be aimed at further scale-up of supercapacitor production in Saxony, Germany, to meet customer demand and continuing the development of supercapacitor and curved graphene technology in new battery products.

An update on Skeleton Technologies' graphene-based supercapacitors

Germany-based Skeleton Technologies has been on the forefront of graphene-based supercapacitors development for many years, and the company recently made some major announcements, including a large (>â¬70 million) financing round, the super-battery project and several strategic customers and projects - including ones with Medcom, Skoda, CAF, Wrightbus and Marubeni.

We recently talked with Skeleton's VP of automotive products, Sebastian Pohlmann, who updated us on the company's business and technology.

Skeleton Technologies enters agreement with CAF Power & Automation for supercapacitors for trams

Skeleton Technologies has signed a contract with CAF Power & Automation, a global manufacturer of electric power solutions for the rail industry, to supply supercapacitors in trams powered by CAF P&’s OESS-s (On Board Energy Storage Systems).

Skeleton’s cells will reportedly be included in Greentech OESS portfolio already used by some of the leading railway companies worldwide to offer cutting edge solutions to energy recovery, peak shaving and catenary-free applications.

Skeleton Technologies raises €29 Million in Series D extension

Skeleton Technologies recently announced the closing of a further â¬29 Million in its Series D round of funding. With this development, the total funding in Round D now amounts to â¬70.4 Million including the â¬41.3 Million announced in November 2020.

This round follows the company’s â¬51 Milion funding by Germany’s Federal Ministry for Economic Affairs and Energy (BMWi) and the Free State of Saxony, announced in March 2021.

Pagination

- Page 1

- Next page