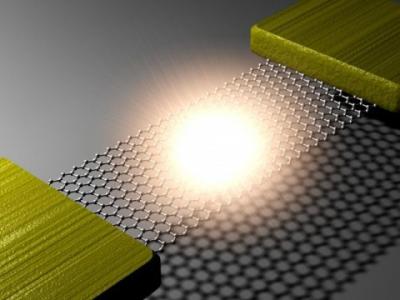

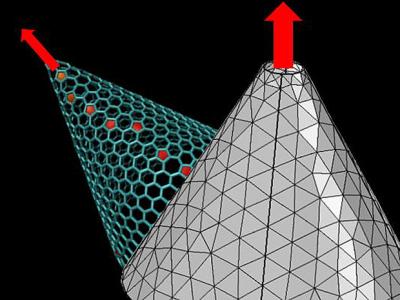

Rice scientists calculate how twisting graphene changes its electrical properties

Researchers at Rice University used computer models to demonstrate that twisting graphene alters its electrical properties, and produce what is known as a flexoelectric effect in which a material exhibits a spontaneous electrical polarization brought on by a strain.

When in flat sheet form, graphene's atoms have a balanced electrical charge. Putting a curve in the graphene plane, however, makes the electron clouds of the bonds on the concave side compress while on the convex side they stretch. This changes the electric dipole moment, which is a measure of the overall polarity and determines how polarized atoms interact with external electric fields.