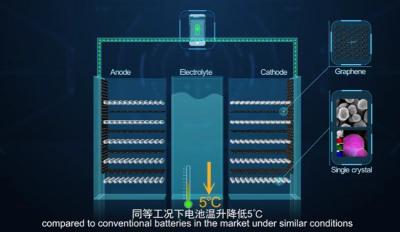

First Graphene demonstrates its graphene-based fire retardant material

First Graphene has provided an update on its development of the FireStop graphene-enhanced fire retardant coating in the form of a video. Development of the FireStop material is being conducted in conjunction with the University of Adelaide as part of the Company’s participation as a Tier 1 participant in the ARC Research Hub for Graphene Enabled Industry Transformation.

The video shows the dramatic effectiveness of FireStop when applied to simple wooden structures. Whereas the untreated structure on the left is totally consumed by fire, the structure treated with the FireStop retardant doesn’t seem to catch fire even after five minutes of trying. Given that fires generally start at specific ignition points, the ability of a graphene-based retardant to stop the ignition is a key feature of the product.