Graphenea is a private European company (based in Spain) focused on the production of high quality graphene for industrial applications. Graphenea produces both CVD graphene (using Aixtron's Black Magic equipment) and Graphene Oxide materials.

Graphenea is a private European company (based in Spain) focused on the production of high quality graphene for industrial applications. Graphenea produces both CVD graphene (using Aixtron's Black Magic equipment) and Graphene Oxide materials.

The company offers graphene on several substrates and can also transfer the graphene to your own substrate in-house.

In 2020 Graphenea launched a dedicated Graphene Foundry. The company can take care of CVD graphene synthesis, transfer and device fabrication and deliver a fully tested graphene-based chip to the customer. This service reduces product development time and costs and Graphenea offers a reliable supply of graphene-based chips from prototyping to scale production.

In 2021, Graphenea updated us that its CVD graphene revenue in 2020 was 1.56 million Euro. The company expects to continue and grow at a CAGR of around 30% in the near future. Its current yearly production capacity is 8,760 200 mm wafers, but the company plans to increase that 25-fold in coming years.

Graphenea's main CVD graphene applications are in Biosensors, Photosensors and Photonics.

Tolosa Hiribidea 76

20018 Donostia-San Sebastian

Spain

MEGAMORPH demonstrates its graphene-based display technology at Displayweek 2024

The EU-funded MEGAMORPH project, which started in 2022, demonstrated its graphene-based display technology at Displayweek 2024.

The idea behind the project is to use CVD graphene sheets (produced by Graphenea, a partner in the project) as the semi-transparent membranes in a Interferometric Modulator Display. These kinds of displays use mechanical micro-mirrors as pixels that modulate the ambient light without using power to generate light. IMOD displays are promising as they can offer very low power operation and high density displays.

Project Next-2Digits launches for next generation of sensors and imagers

A new Horizon Europe funded project was launched in October 2023. With a consortium of 11 partners from 8 different countries, the Next-2Digits project aims to develop the next generation of sensors and imagers enabled by 2D materials digital integration. Next-2Digits will run for 3 years and 3 months.

Coordinated by the National Technical University of Athens, Next-2Digits benefits from the presence of academic, research and industrial teams, whose areas of work span from graphene and 2D materials synthesis, characterization, manipulation, and integration, as well as in the fields of photonics, material science, application-based integration technologies and validation.

Researchers suggest a perovskite-graphene device for X-ray detection

Researchers at Graphenea, University of Utah and Kairos Sensors have examined a perovskite-based graphene field effect transistor (P-GFET) device for X-ray detection.

The device architecture consisted of a commercially available GFET-S20 chip, produced by Graphenea, with a layer of methylammonium lead iodide (MAPbI3) perovskite spin coated onto the top of it. This device was exposed to the field of a molybdenum target X-ray tube with beam settings between 20 and 60 kVp (X-ray tube voltage) and 30–300 μA (X-ray tube current). Dose measurements were taken with an ion-chamber and thermo-luminescent dosimeters and used to determine the sensitivity of the device as a function of the X-ray tube voltage and current, as well as source-drain voltage.

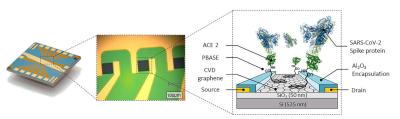

Graphenea takes part in effort to achieve ultrasensitive detection of SARS-CoV-2 spike protein using graphene field-effect transistors

Researchers from Graphenea, Ikerbasque, BCMaterials, Center for Cooperative Research in Biomaterials (CIC biomaGUNE) of the Basque Research and Technology Alliance (BRTA), University of the Basque Country UPV-EHU, University of Trieste and Universidade da Coruña recently reported a graphene field effect transistors (GFET) array biosensor for the detection of SARS-CoV-2 spike protein, using the human membrane protein involved in the virus internalisation: angiotensin-converting enzyme 2 (ACE2).

By finely controlling the graphene functionalization, by tuning the Debye length, and by deeply characterizing the ACE2-spike protein interactions, the team managed to detect the target protein with an extremely low limit of detection (2.94 aM).

Graphenea expands its mGFET product line with an integrated reservoir for biosensing in liquid

Graphenea recently upgraded its mGFET line of products with a built-in reservoir for liquids. This enhancement increases ease of use for biosensing and implementation in clinical testing and rapid screening.

The mGFET product line is designed to minimize barriers to adoption of graphene as a biosensor. The product was launched at the same time as the Graphenea Card, a socket for housing the mGFET and interfacing with measurement electronics. The addition of the built-in reservoir lets the user focus on the biochemistry, without worrying about producing the graphene or the sensor, or about interfacing.

Graphenea reports financial figures for 2022 with 34% growth rate

Graphenea recently released its financial results for 2022, highlighting an impressive growth rate and the successful launch of a new business.

Consolidated revenue for 2022 amounted to €4.18 million , reflecting a 34% year-over-year growth rate. Additionally, the Company achieved a positive EBITDA of €0.78 million , demonstrating a strong financial performance.

Graphenea launches specialty chemical spin-off Kivoro

Graphenea has launched a specialty chemicals spin off, called Kivoro. The new company will be focused on creating solutions for industrial challenges.

Graphenea will continue to operate as a graphene producer, with Kivoro taking lead on applications development in various industries like composites, construction, and more.

Graphenea reports excellent market reaction to its mGFET devices

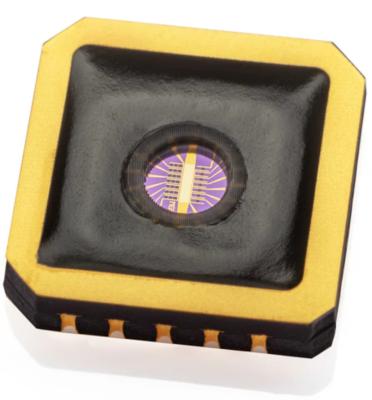

In June 2022, Graphenea launched its latest product out of its Graphene Foundry, the mGFET, fully-packaged mini graphene-based field effect transistors.

Graphenea now updates that the market demand for these products has been excellent, and it has run out of stock. The company is now working to produce more mGFET devices and restock.

The mGFETs are Graphenea's highest value-chain products, which are manufactured and packaged in chip carriers, and can be used together with the Graphenea Card for seamless sensor development (which was released earlier in 2022, and has also seen very good reception in the industry).

Graphmatech, Graphenea, and Northvolt produce graphene oxide from recycled EV batteries

Graphmatech, Graphenea, and Northvolt have announced their success in up-cycling end-of-life EV batteries into graphene oxide at industrial pilot scale. This breakthrough uses the material left after Northvolt has extracted valuable metals and minerals. Until now, that remaining material was left as waste.

Emma Nehrenheim, Chief Environmental Officer of Northvolt, comments: The upcycling of graphene oxide from recycled batteries represents a great development in our pursuit of a sustainable battery industry in Europe. Batteries contain an abundance of valuable materials which we can recover to reduce our dependence on mining and producing fresh materials. We are proud to have contributed to this development.

Graphenea, Lantania and UPM develop graphene-enhanced additive for cement and concrete

Graphenea, Lantania (an international group that builds large transport, water and energy infrastructures) and the Polytechnic University of Madrid (UPM) recently developed a graphene-enhanced additive that enhances the expected useful life of concrete by 50%, as well as its resistance to adverse environmental conditions and its mechanical behavior. After verifying its effectiveness in the laboratory, the new additive was tested on a non-structural element of the Almudévar Reservoir construction project.

The test was conducted by adding an improved graphene admixture to concrete with a 30 MPa compressive strength. Its overall efficacy was evaluated during mixing in the concrete plant, when still fresh and through noting the effects on the concrete during transport and placement. Mechanical behavior and durability tests in aggressive environments were then carried out.

Pagination

- Page 1

- Next page