Carbyne was made for the first time - said to be stronger than graphene

Scientists at the University of Vienna in Austria have managed to synthesize carbyne for the first time. Carbyne has been theorized in the past, and said to be stronger than graphene and posses other intriguing properties. However, this is the first time that a stable form was actually made.

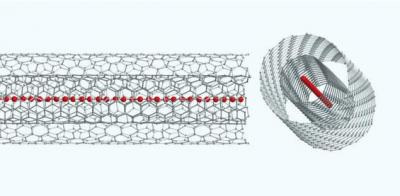

Creating a stable form was technically difficult because carbyne is composed of a long one-dimensional chain of carbon atoms linked one to the other. To do this, the scientists took two sheets of graphene and rolled them together and then used this stable superstructure to fashion the carbyne. The new structure is 6,400 atoms long and the material's potential applications will need to be explored.