Researchers design a butterfly-inspired multisensory neuromorphic platform for integration of visual and chemical cues

It is a known fact that animals require the integration of cues collected from multiple sensory organs to enhance the overall perceptual experience and thereby facilitate better decision-making in most aspects of life. However, despite the importance of multisensory integration in animals, the field of artificial intelligence (AI) and neuromorphic computing has primarily focused on processing unisensory information. This lack of emphasis on multisensory integration can be attributed to the absence of a miniaturized hardware platform capable of co-locating multiple sensing modalities and enabling in-sensor and near-sensor processing.

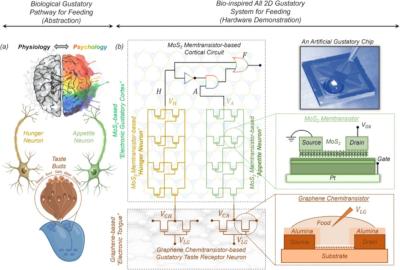

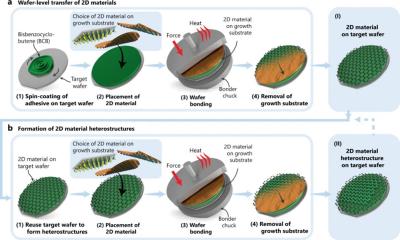

a) A simplified abstraction of visual and chemical stimuli from male butterflies and visuo-chemical integration pathway in female butterflies. b) Butterfly-inspired neuromorphic hardware comprising of monolayer MoS2 memtransistor-based visual afferent neuron, graphene-based chemoreceptor neuron, and MoS2 memtransistor-based neuro-mimetic mating circuits. Image credit: Advanced Materials

In their recent study, researchers at Penn State University addressed this limitation by utilizing the chemo-sensing properties of graphene and the photo-sensing capability of monolayer molybdenum disulfide (MoS2) to create a multisensory platform for visuochemical integration.