Graphene production systems maker planarTECH launches an equity crowdfunding campaign to support its future growth potential

UK-based planarTECH is launching an equity crowdfunding campaign at on Seedrs, as part of Graphene-Info's Graphene Crowdfunding Arena. planarTECH aims to expand its current business and also initiate new graphene endeavors.

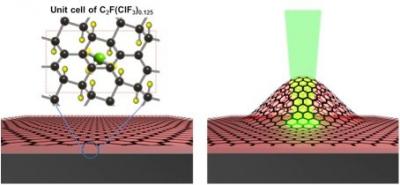

planarTECH, founded in 2014, supplies CVD equipment for the production of high quality graphene sheets, as well as other 2D materials. The company was focused on research institutes, and already sold over 65 systems with a customer list that includes Manchester University, the University of Cambridge, Stanford University and the National University of Singapore.