Graphene and boron nitride structure holds promise for fuel cells

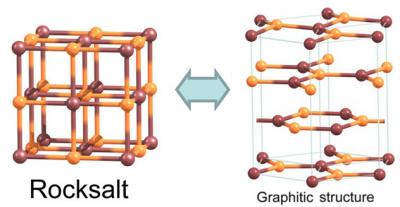

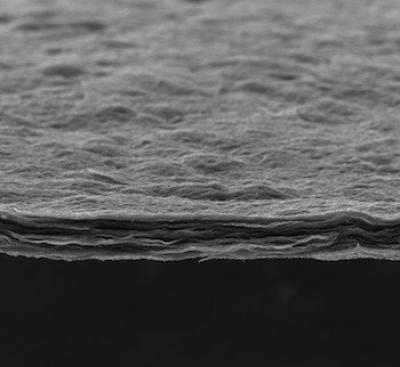

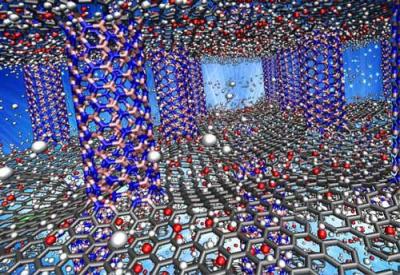

Researchers at Rice University have found that layers of graphene, separated by nanotube pillars of boron nitride, may be a suitable material to store hydrogen fuel in cars. The boron nitride pillars are situated between graphene layers to make space for hydrogen atoms, similarly to spaces between floors in a building. The actual challenge is to make the atoms enter and stay in sufficient numbers and exit upon demand.

In their latest molecular dynamics simulations, the researchers found that either pillared graphene or pillared boron nitride graphene would offer abundant surface area (about 2,547 square meters per gram) with good recyclable properties under ambient conditions. Their models showed adding oxygen or lithium to the materials would make them even better at binding hydrogen.