Scientists use lasers to 3D print graphene foams

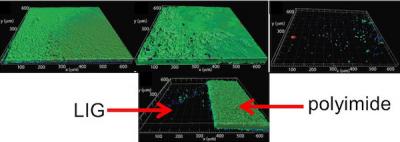

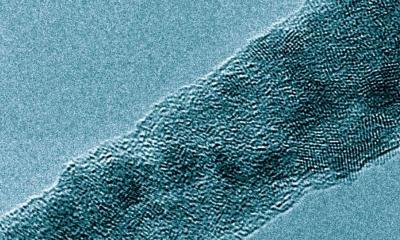

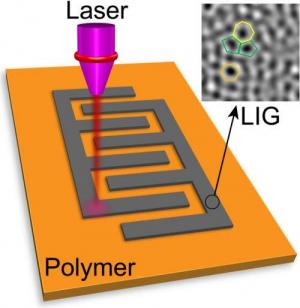

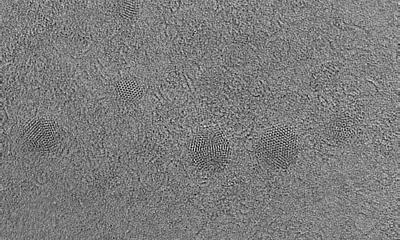

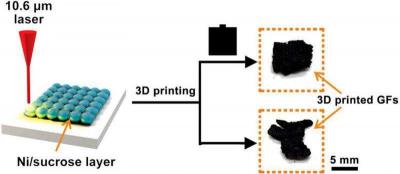

Researchers at Rice University and China's Tianjin University have used 3D laser printing to fabricate centimeter-sized graphene objects. The team has demonstrated the making of graphene foams from non-graphene starting materials, in a method that could reportedly be scaled for additive manufacturing applications with pore-size control. The process is conducted at room temperature, without the need for molds. The rather unusual starting materials are powdered sugar and nickel powder.

3D laser printers work differently than the more familiar extrusion-based 3D printers, which create objects by squeezing melted plastic through a needle as they trace out two-dimensional patterns. In 3D laser sintering, a laser shines down onto a flat bed of powder. Wherever the laser touches powder, it melts or sinters the powder into a solid form. The laser is rastered, or moved back and forth, line by line to create a single two-dimensional slice of a larger object. Then a new layer of powder is laid over the top of that layer and the process is repeated to build up three-dimensional objects from successive two-dimensional layers.