Skoltech team patents method for defect-free graphene for flexible transparent electronics

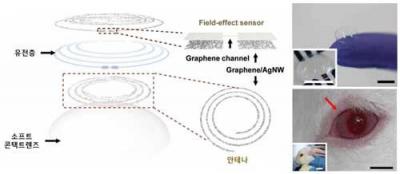

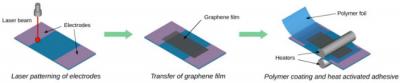

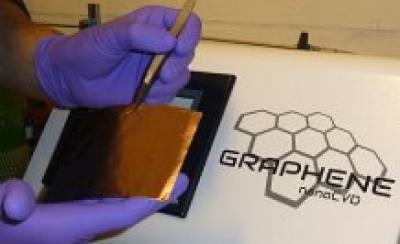

Skoltech researchers have patented a method that enables producing arbitrarily shaped functional graphene components on a transparent substrate with 100-nanometer resolution, which could be especially suited for flexible and transparent electronics. The new approach reportedly helps avoid defects that arise during graphene transfer between substrates and strongly affect the material’s quality.

“Flexible and transparent electronics is typically associated with wearable biosensors that monitor vital signs, such as heart rate, breathing, and blood oxygenation, and relay them to a smartphone or fitness band,” Skoltech PhD student Aleksei Shiverskii, one of the inventors, said. “An affordable and efficient technology that at first may seem impractical soon becomes a ubiquitous and indispensable appliance, like a bluetooth electric kettle or a wifi vacuum cleaner. I believe that someday flexible and transparent electronics will become a fixture, too.”