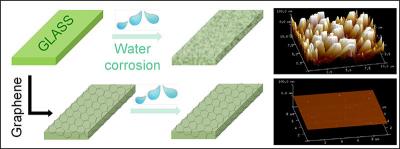

Graphene coating may solve the glass corrosion problem

Researchers at the Center for Multidimensional Carbon Materials (CMCM) within the Institute for Basic Science (IBS), have demonstrated a graphene coating that protects glass from corrosion. Their research has been said to hold potential for solving problems related to glass corrosion in several industries.

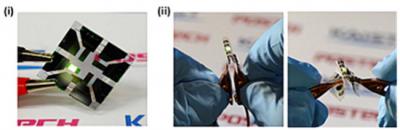

The IBS scientists grew graphene on copper and transferred either one or two atom-thick layers of graphene onto both sides of rectangular pieces of glass. The effectiveness of the graphene coating was evaluated by water immersion testing and observing the differences between uncoated and coated glass. After 120 days of immersion in water at 60 C, uncoated glass samples had significantly increased in surface roughness and defects, and reduced in fracture strength. In contrast, both the single and double layer graphene-coated glasses had essentially no change in both fracture strength and surface roughness.