Penn scientists design unique graphene-based threefold sensor

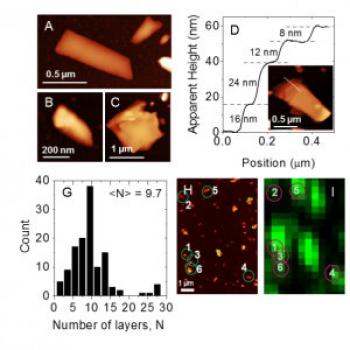

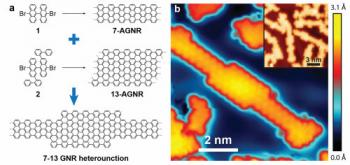

Researchers at Penn University designed a unique graphene-based sensor that works in three ways simultaneously. Since proteins trigger three different types of signals, the sensor can calculate that data to produce sensitive and accurate results, far superior to typical one-trigger sensors. This integration of data from multiple factors on chip can be greatly beneficial to various fields that require sensing abilities, like advanced disease detection.

This technique is said to provide more accurate data on the quantity of a given protein in a sample, and could also be used to eventually make a single sensor that could detect a wide range of triggers. The researchers' sensors are built with a base of silicon nitride, coated with a layer of graphene. Graphene’s extreme thinness and electrical properties allow for the mechanical, electrical, and optical modes to operate simultaneously without interfering with one another, and it is also helpful since it is carbon-based and so it is an attractive bonding surface for proteins.