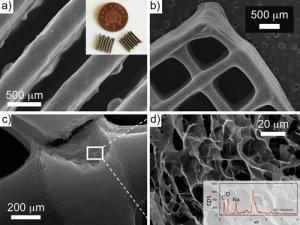

Meandering boundaries may turn out to be advantages

Researchers at Rice University reached the conclusion that grain boundaries (the nanoscale places where individual grains of graphene stitch the sheet together), which are at times considered defects, may in some cases toughen polycrystalline sheets and may also create a band gap.

The scientists explain that at certain angles, these meandering boundaries relieve stress that would otherwise weaken the sheet. Alleviating this stress can enhance graphene's strength, compared to straight boundaries.