A new watch by Zenith to feature a graphene-CNTs hairspring

The Swiss watch manufacturer, Zenith, will be launching a new version of their longtime flagship watch, the El Primero, which will sport a hairspring based on a matrix of carbon nanotubes and graphene. The new watch will retail in the neighborhood of $10,000.

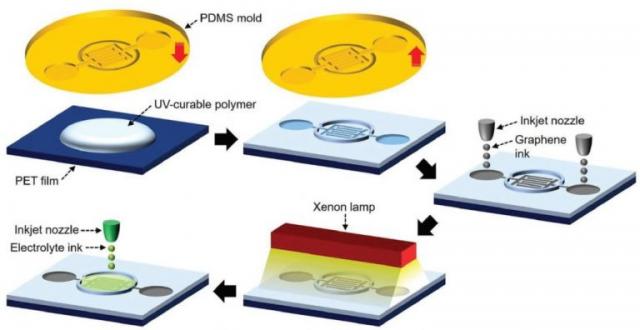

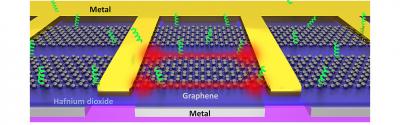

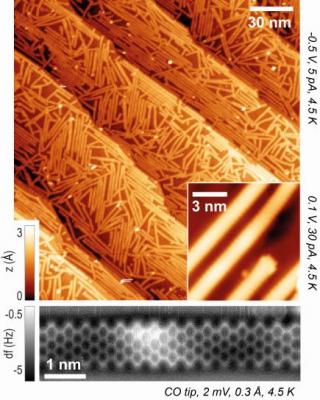

The new Defy El Primero 21 will see many upgrades and changes, among which is the use of this new graphene-enhanced composite as Zenith’s proprietary design that is highly resistant to magnetism and temperature variations like many of the best silicium examples currently in use. Like silicium parts, Zenith’s carbon hairsprings are made with a photolithography process, but one that grows the parts on a silicium wafer, rather than etching them from one. A complex series of chemical and gaseous baths and reactions grow the composite at a molecular level and give it outstanding flex characteristics.