Elecjet to launch a Kickstarter campaign for its new graphene-enhanced USB-C / A fast charging power bank

Elecjet, developer of USB C PD and Graphene Battery technology for fast charging, will be launching a Kickstarter campaign on February 13th, for its Apollo Traveler: an advanced graphene-enhanced USB-C / A fast charging power bank.

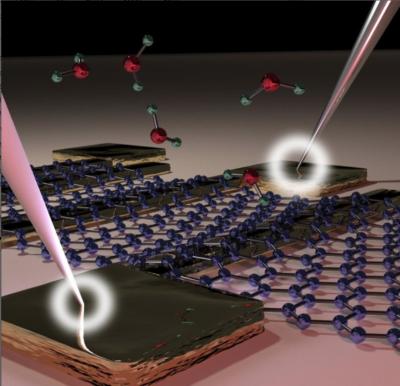

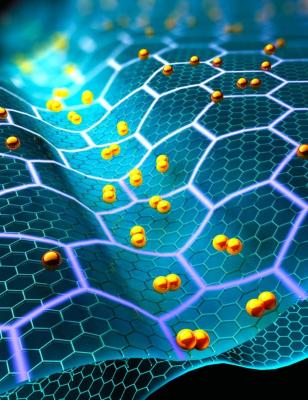

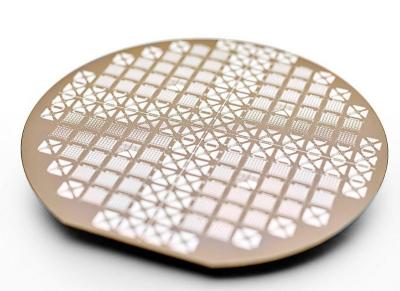

The company explained that the Apollo Traveler uses graphene layers to cover the negative pole and positive pole to achieve a smaller internal resistance and better conductivity. Elecjet also stated that it "reinforced graphene composite layers inside the power bank, making overheating issues a thing of the past". The graphene for the battery is provided by CellsX.