Researchers shed light on ionic interactions with graphene and water

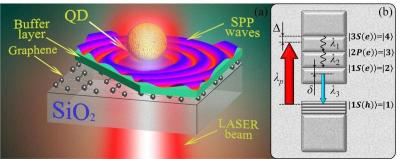

Researchers led by Northwestern University engineers and Argonne National Laboratory scientists have reached new findings regarding the role of ionic interaction within graphene and water. Their insights could open the door to the design of new energy-efficient electrodes for batteries or provide the backbone ionic materials for neuromorphic computing applications.

"Every time you have interactions with ions in matter, the medium is very important. Water plays a vital role in mediating interactions between ions, molecules, and interfaces, which lead to a variety of natural and technological processes," said Monica Olvera de La Cruz, Lawyer Taylor Professor of Materials Science and Engineering, who led the research. "Yet, there is much we don't understand about how water-mediated interactions are influenced by nanoconfinement at the nanoscale."