Graphene oxide helps achieve efficient air processed perovskite solar cells via scalable technique

A research team, led by Dr. Luigi Angelo Castriotta at the at University of Rome Tor Vergata's CHOSE Center for Hybrid and Organic Solar Energy, has reported impressive results on methylammonium free perovskites processed in air, using a scalable technique based on infrared annealing and potassium doped graphene oxide as an interlayer.

The team reached excellent efficiencies of 18.3% and 16.10% on 0.1cm2 cell and on 16cm2 module respectively, with enhanced stability compared to the standard multi cation reference.

Graphene coating could help create higher energy density lithium-ion batteries

Researchers at Northwestern University and Clemson University in the U.S, along with researchers from Sejong University in Korea, have examined the origins of degradation in high energy density LIB cathode materials and developed graphene-based strategies for mitigating those degradation mechanisms and improving LIB performance.

Their research could be valuable for many emerging applications, particularly electric vehicles and grid-level energy storage for renewable energy sources, such as wind and solar.

Researchers examine novel inkjet-printed graphene for high‐quality large‐area electronics

Researchers from the University of Nottingham’s Centre for Additive Manufacturing (CfAM) have reported a breakthrough in the study of 3D printing electronic devices with graphene.

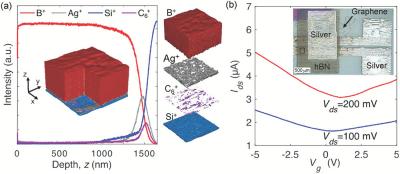

Characterization of the fully inkjetâprinted graphene/hBN FET. Photo from article

Characterization of the fully inkjetâprinted graphene/hBN FET. Photo from article

The scientists utilized an inkjet-based 3D printing technique to deposit inks that contained flakes of graphene, in a promising step towards replacing single-layer graphene as a contact material for 2D metal semiconductors.

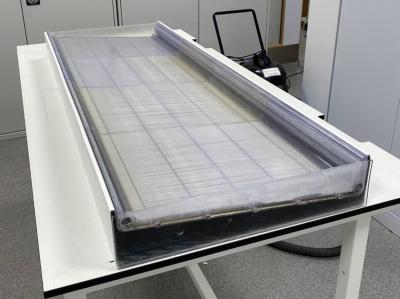

WMG and Senergy Innovations develop graphene-enabled all polymer solar thermal cell

Researchers led by Professor Tony McNally, from WMG, at the University of Warwick, in partnership with Senergy Innovations, have launched the first nanomaterial enabled all polymer solar thermal cell. This achievement was supported by funding from BEIS (Department for Business, Energy & Industrial Strategy).

The thermal properties of the polymers that were used were modified to enable heat from sunlight to be transferred with high efficiency to heat water in a low cost and sustainable way. The modular design of the cells reportedly allows for the rapid construction of a solar thermal cell array on both domestic and industry roofing.

Graphene-perovskite solar farm trial up and running in Greece

An experimental graphene-based perovskite solar farm has been operating in Greece for several months, and early results are said to be very promising when it comes to power output and efficiency.

Located at the Hellenic Mediterranean University in Crete and spearheaded by the EU’s Graphene Flagship, the new solar farm consists of nine grapheneperovskite panels with a total area of 4.5m2 and a total output of approximately 261 watt-peak (Wp).

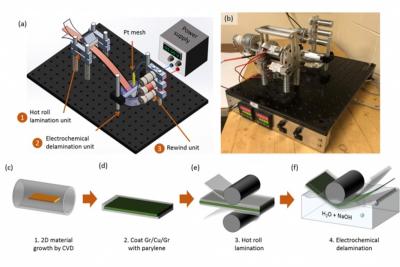

MIT team reports new roll-to-roll process for production of large sheets of high-quality graphene

Researchers at MIT have developed a new roll-to-roll production process for large sheets of high-quality graphene, which the team says could lead to ultra-lightweight, flexible solar cells, and to new classes of light-emitting devices and other thin-film electronics.

The new manufacturing process, which the team says should be relatively easy to scale up for industrial production, involves an intermediate buffer layer of material that is key to the technique’s success. The buffer allows the ultrathin graphene sheet, less than a nanometer (billionth of a meter) thick, to be easily lifted off from its substrate, allowing for rapid roll-to-roll manufacturing.

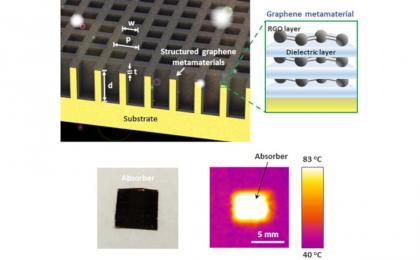

Researchers develop a graphene metamaterial film that absorbs sunlight with minimal heat loss

Researchers from Swinburne University developed a graphene-based highly efficient solar absorbing film that absorbs sunlight with minimal heat loss. The film rapidly heats up in an open environment and has great potential in solar thermal energy harvesting systems - in addition to other applications such as thermophotovoltaics (directly converting heat to electricity), solar seawater desalination, light emitters and photodetectors.

This is the 2nd-generation material developed by the same group - now with a thickness of only 30 nm and improved performance and longer lifetime. The researchers have now created a first prototype and also suggest a scalable low-cost manufacturing process.

Verditek raises over USD$660,000 in share issue

Verditek, developer of lightweight solar panels in Italy, recently raised GBP 505,750 (USD 663,600/EUR 578,219) before expenses, which it plans to use mainly to fund commercial opportunities announced earlier this year. Some of the proceeds will go towards the joint development program with Paragraf, under which the two are working on a silicon/graphene integrated solar cell.

Earlier this year, the Company announced framework, distribution and collaboration agreements and a number of trials with companies it described as big players in their respective markets.

Graphene helps in creating efficient tandem perovskite solar cell

Italian researchers from two Italian institutions have used graphene to develop a perovskite-silicon solar cell - a promising new solar technology - with an impressive conversion efficiency of 26.3%.

The researchers added graphene to the titanium dioxide electron selective layer used in a perovskite solar cell in order to increase chemical stability. The two-terminal cell was made by stacking two sub-cells which were fabricated and optimized separately. The new device blends the advantages of thin-film perovskite and silicon-based heterojunction cells, according to its developers.

New Graphene Flagship "Spearhead Projects" get €92 million in funding

The Graphene Flagship has announced the launch of eleven new "Spearhead Projects", each developed to take graphene-enabled prototypes to commercial applications. Now, the Graphene Flagship has committed 45 million Euro to invest in eleven commercialization projects led by key industrial partners in Europe such as Airbus, Fiat-Chrysler Automobiles, Lufthansa Technik, Siemens, and ABB. Notably, the project partners will also co-fund the projects with a further combined contribution of 47 million Euro, showing their interest in the development of graphene-enabled products.

The newly launched projects combine the results of the Graphene Flagship's innovative scientific research with the ambitions of commercial partners for marketable applications. This initiative will bring the number of companies involved in the Graphene Flagship to 78, which makes up nearly half of the whole consortium.

Pagination

- Previous page

- Page 2

- Next page