Researchers at Queen’s University in Kingston, Canada have developed a simple yet effective exfoliation process for producing few-layer graphene nanoplatelets (FL-GNPs). Utilizing this one-step, chemical and solvent-free process the researchers were able to convert graphite flakes (+100 mesh, purity >97%) into FL-GNPs at a high yield (90%) and to subsequently form thermoplastic/FL-GNPs composites with improved electrical and mechanical properties.

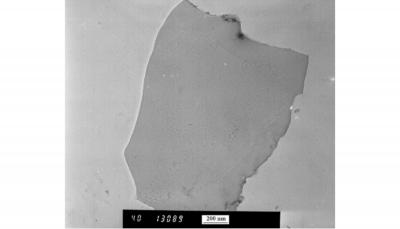

TEM image of isolated FL-GNP

TEM image of isolated FL-GNP

The exfoliated graphene nanoplatelets had a high specific surface area (325 m2/g), an aspect ratio above 500 (approximate lateral dimensions of 2µm and thickness of 3.5 nm), and a Raman D/G ratio of 0.3; indicating a structure with few defects. The flexural modulus of polyamide/FL-GNP composites containing 15 volume % FL-GNPs improved from 1850 MPa to 5,080 MPa while the electrical conductivity rose from 5x10-14 S/m to 21 S/m. Surface-coating the FL-GNPs through the addition of a coating agent during the last stages of the exfoliation process rendered the FL-GNPs more hydrophilic, thus, forming stable dispersions in water.

Developed by Drs. Osayuki Osazuwa and Marianna Kontopoulou, this patent-pending exfoliation process utilizes moderate mechanical shear, in the absence of any additives or a liquid medium, to exfoliate the graphite flakes into FL-GNPs. This one-step, low-temperature (150-200 °C) process is inherently scalable and, with energy consumption estimated at 2-4 kWh/kg, very cost-effective. As such, it addresses many of the limitations associated with known exfoliation processes.

Queen’s University is currently seeking industrial partners interested in commercializing the technology. For additional information please contact Jason Hendry, Assistant Director of Commercial Development at jason.hendry@queensu.ca