Carbon nanotubes and graphene - properties, applications and market

Graphene and CNTs are both made of carbon atoms. A carbon nanotube can be thought of as a sheet of graphene (a hexagonal lattice of carbon) rolled into a cylinder. Accordingly, CNTs can be used as a starting point for making graphene, by “unzipping†them.

Both graphene and CNTs have exceptional mechanical and electronic properties, which can often be similar. Hence, they are often regarded as rivals for a host of similar applications. It should be noted that there is also an area of research focused on combining graphene and CNTs and using them together for various application like electronics, batteries, sensors and more.

Despite these similarities between the materials, there are still differences between them. While graphene is considered 2D, CNTs are often regarded and 1D. Also, graphene (when ideally structured with atom purity and perfect honeycomb lattice) is a zero-band-gap semiconductor, whereas single-walled CNTs show either metallic or semiconducting properties, with a bandgap that varies from zero to about 2 eV.

Working with CNTs is often considered challenging due to the intrinsic difficulty in positioning them accurately and connecting them. Graphene, which came into the scene later than veteran CNTs, can be easier to interconnect and dope, but carries its own set of challenges, like extraction, manipulation and stability burdens.

Carbon - a building block for many materials

Carbon is a non-metallic chemical element often regarded as a common element of all known life. It is the 15th most abundant element in the Earth's crust, and the fourth most abundant element in the universe by mass.

Carbon can be found in many forms, each of which has its own physical characteristics. These forms include well-known materials like diamond and graphite, that only differ in physical properties due to variations in the arrangement of atoms in their structures. Other, less well-known forms are fullerenes - spherical, closed-cage fullerenes are called buckerminsterfullerenes, or “buckyballs,†and cylindrical fullerenes are called nanotubes. Another form, composed only of carbon atoms in a flat, 2D lattice structure is called graphene. Other forms of carbon atoms arrangements exist,like amorphous carbon, Q-carbon and more.

What is graphene?

A single, 2 dimensional layer of graphite is called graphene. So, graphene is basically a sheet of carbon atoms arranged in a hexagonal layout. Graphene is considered the first 2D material ever discovered, and is also called a â€wonder material†thanks to an enormous group of properties it holds. For example, graphene is one of the strongest materials in universe, has superior thermal and optical properties, excellent tensile strength, relative transparency, amazing electrical conductivity, and impermeability to most gases and liquids and more.

Graphene’s many attributes make it an attractive material for researchers and developers, which are working hard all over the world to find endless uses for the material. Graphene’s tial is vast, and the applications include: touchscreens (for LCD or OLED displays), computer chips, batteries. energy generation, supercapacitors, medical equipment, water filters, solar cells and more.

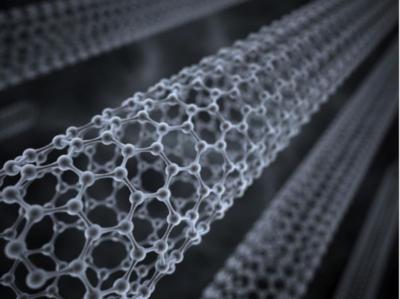

What are carbon nanotubes?

Carbon nanotubes (often abbreviated to CNTs) are cylindrically-shaped molecules made of carbon atoms. A sheet of graphene can be rolled-up to make a carbon nanotube. CNTs can be single-walled (SWCNT) if made from one layer of carbon atoms, or multi-walled (MWCNT) when consisting of several layers of graphene sheets. In fact, carbon nanotubes come in various diameters, lengths, and functional group content which can tailor their use for specific applications.

The properties of CNTs change according to their characteristics. For instance, MWCNTs are usually conducting while SWCNTs can be electrically conducting, display the properties of a semiconductor or be non-conducting. Factors like structure, length, surface area, surface charge, size distribution, surface chemistry, and agglomeration state, as well as purity of the samples, have great impact on the properties of carbon nanotubes.

CNTs have unique mechanical, thermal andelecronic properties that make them intriguing for the development of new materials: impressive mechanical tensile strength,light-weight, good thermal conductivity and much more.

These properties make carbon nanotubes attractive for electronic devices, sensors and biosensors, transistors, batteries, hydrogen storage cells, electrical-shielding applications and more.

Carbon Nanotubes have been around since the early 1990s and already found some commercial use in the fields of engineering plastics, polymers, displays, anti corrosion paints, thin films and coatings, transparent and non-transparent conductive electrodes, coatings and anti-static packaging and more. In addition, active research is ongoing in fields like batteries, fuel cells, solar cells, water desalination and more.

However, after the initial hype, revolutions failed to happen and many gave up on CNTs. But this is not to say that they do not have actual potential and interest in them is reappearing in the research community in the last few years. As was said, they have found some uses and more are estimated to follow and the potential of CNTs is not considered to have been exhausted.

CNTs are available in bulk quantities up to metric ton quantities. Production capacities for CNTs have been scaled up considerably over the years and currently exceed several thousand tons per year. It is estimated that several CNT manufacturers have over 100 ton per year production capacity for multi walled nanotubes. It seems that the capacity for the production of MWNTs exceeds that of SWNTs, although there is an oversupply in the market. SWNTs are much more expensive and difficult to manufacture than MWCNTs, and there is not yet a distinct large-scale market for SWNTs, which is needed to drive down the production cost.

In terms of prices, SWCNTs are the most expensive type of CNTs, with a price tag of up to $100,000 per Kg - compared to around $100 per Kg for MWCNTs). Some manufacturers sell an intermediate type of CNTs, sometimes called few-wall CNTs. Prices for this type are varies, but can be about $1,000 per Kg. (estimated prices as per 2018).

Nanoxplore expands capacity in Quebec plant to accommodate higher customer volumes

NanoXplore has announced that it has increased the production capacity of its St-Clotilde, Quebec plant to meet an existing customer’s need for increased graphene-enhanced SMC parts in an active program.

This capacity expansion, which is part of its 5-year strategic plan and related to the SMC lightweighting initiative, begins immediately. This expansion, in two phases, will contribute $2 Million in incremental revenues during calendar 2024 and once fully scaled-up, is expected to contribute $8 Million to $10 Million annually beginning in 2025.

Researchers succeed in contacting individual graphene nanoribbons using carbon nanotube electrodes

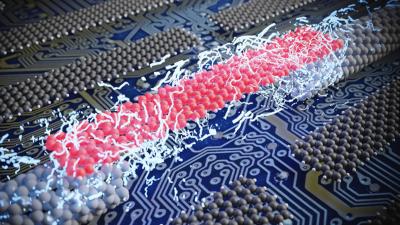

Researchers from Empa and ETH Zurich, in collaboration with partners from Peking University, the University of Warwick and the Max Planck Institute for Polymer Research, have succeeded in attaching electrodes to individual atomically precise graphene nanoribbons, paving the way for precise characterization of the ribbons and their possible use in quantum technology.

Researchers attach carbon nanotube electrodes to individual atomically precise nanoribbons. (Image credit: Empa, from: Nanowerk)

In the coming decades, quantum technology is expected to provide various technological breakthroughs: smaller and more precise sensors, highly secure communication networks, and powerful computers that can help develop new drugs and materials, control financial markets, and predict the weather much faster than current computing technology ever could. To achieve this, there is a need so-called quantum materials: substances that exhibit pronounced quantum physical effects. One such material is graphene. Giving it a ribbon-like shape, for example, gives rise to a range of controllable quantum effects.

PlanarTECH on its way to its best year ever, gets ready for its second crowdfunding round

UK-based PlanarTECH offers R&D and production-scale equipment and services for all classes of emerging 2D materials and carbon-based materials such as CNTs and CVD diamonds. In 2020 planarTECH launched a successful equity crowdfunding campaign as it aims to expand its business and enter new markets such as industrial CVD graphene production systems and material production.

We have recently talked to the company's CEO, J. Patrick Frantz, who gives us the latest business and technology updates from PlanarTECH.

Q: Can you update us on your latest business activities, with a focus on graphene?

We had a very difficult time during the pandemic, as many companies did. From July 2020 through June 2021 we shipped just one CVD system. However, we started to see a resumption of customer activity towards the end of 2021 as labs reopened and people around the world got back to work. For 2022, we’re seeing a complete recovery and are on our way to the best year we’ve ever had in terms of sales.

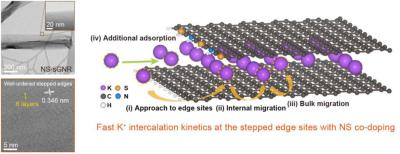

Korean researchers fabricate nitrogen and sulfur co-doped graphene nanoribbons for enhanced potassium batteries

A research team, led by Professor Yu Seung-ho of the Department of Chemical and Biological Engineering at Korea University, Seoul National University's Professor Yuanzhe Piao and Sogang University's Professor Back Seo-in, has fabricate nitrogen and sulfur co-doped graphene nanoribbons with stepped edges, elucidating the migration barrier and enhancing the electrochemical performance of potassium batteries.

Potassium has shown promise for large-capacity non-lithium battery cells, because it is affordable, abundant, and has a low redox potential (-2.93V) close to that of lithium ion (-3.04V). Carbon-based nanomaterials, which are chemically stable and lightweight, are popular anode materials used in potassium batteries. However, the high energy barrier between electrochemical intercalation and deintercalation of potassium ions induces adsorption/desorption reactions, resulting in the storage of potassium ions only on the surface of carbon and lowering the energy density during battery assembly. As such, the smooth intercalation/deintercalation of potassium is extremely important in obtaining high-performance potassium batteries.

New method creates sub-10-nm GNRs from squashed carbon nanotubes

Researchers at Shanghai Jiao Tong University, Stanford University, and other US and China institutes have designed a strategy for creating graphene nanoribbons (GNRs) with smooth edges that are below 10 nm in width. This new method is based on the use of squashed carbon nanotubes (CNTs).

The team explained that the idea behind this new work is that if carbon nanotubes (CNTs) can be squashed into GNRs, it would be possible to produce narrow (sub-5-nm wide) GNRs from CNTs that have small diameters. The team said that the GNRs prepared using this method would be much narrower than those obtained by previous methods.

Researchers develop flexible and self-adaptive airflow sensor enabled by a graphene and CNTs membrane

Researchers at the Ningbo Institute of Materials Technology and Engineering (NIMTE) of the Chinese Academy of Sciences (CAS), led by Prof. Chen Tao, have developed a flexible and self-adaptive airflow sensor enabled by a graphene and CNTs membrane, which is mediated by the reversible microspring effect.

Airflow sensors based on the mechanical deformation mechanism have been drawing increasing attention thanks to their excellent flexibility and sensitivity. However, fabricating highly sensitive and self-adaptive airflow sensors via facile and controllable methods remains a challenge. Recently, inspired by the bats' wing membrane which shows unique airflow sensing capacity, the researchers at NIMTE prepared graphene/single-walled nanotubes (SWNTs)-Ecoflex membrane (GSEM), which can be arbitrarily transferred and subsequently adapt to diverse flat/bend and smooth/rough surface. Relying on the reversible microspring effect, the researchers developed a highly sensitive and self-adaptive GSEM-based airflow sensor.

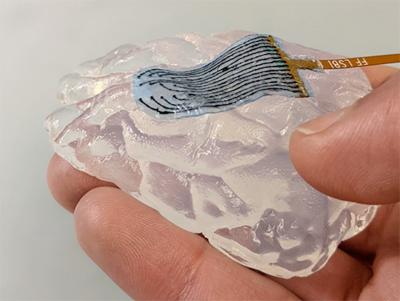

Graphene and CNTs assist in creating viscoelastic electrode arrays

A team of scientists from Harvard’s Wyss Institute and John A. Paulson School of Engineering and Applied Sciences (SEAS) has created flexible, metal-free electrode arrays that conform to the body. This conformity allows, for example, electrical impulses to be recorded and stimulated with lower required voltages, enabling their use in hard-to-reach areas of the body, and minimizes the risk of damage to delicate organs.

Arrays of metal electrodes are currently used in medical procedures that require monitoring or delivering electrical impulses in the body, such as brain surgery and epilepsy mapping. However, the metal and plastic materials that comprise them are stiff and inflexible while the body’s tissues are soft and malleable. This mismatch limits the places in which electrode arrays can be successfully used, and also requires the application of a large amount of electrical current in order to jump the gap between an electrode and its target. In this new work, the team tackles this issue and delivers soft and conformable graphene and CNTs based electrodes.

New ICE-Batt project sets out to optimize battery technology using graphene and CNTs

CPI and Thomas Swan have teamed up with Johnson Matthey (JM), a company focused on sustainable technologies, to explore how to best optimize battery technology using graphene and CNTs.

The ICE-Batt project receives funding support from the Faraday Battery Challenge, managed by Innovate UK the UK’s innovation agency to enable the investigation of how innovative carbon nanotubes (CNTs) and graphene nanoplatelets (GNPs) can improve battery performance. In addition, the project will explore how to improve the green credentials of battery processing.

Duke team creates fully recyclable printed electronics

Researchers at Duke University have created transistors with three carbon-based inks. The all-carbon thin-film transistors were made using crystalline nanocellulose as a dielectric, carbon nanotubes as a semiconductor, graphene as a conductor and paper as a substrate. This type of component could assist in addressing the environmental problem of accumulation of electronics that are non-recyclable.

Silicon-based computer components are probably never going away and we don’t expect easily recyclable electronics like ours to replace the technology and devices that are already widely used, said Professor Aaron Franklin, an electrical engineer at Duke University. But we hope that by creating new, fully recyclable, easily printed electronics and showing what they can do, that they might become widely used in future applications.

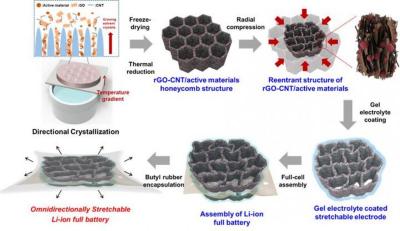

KIST researchers develop stretchable graphene-based lithium-ion battery

A research team from the Korea Institute of Science and Technology (KIST) recently developed a graphene-based lithium-ion battery that is flexible enough to be stretched.

Dr. Jeong Gon Son's research team at the Photo-Electronic Hybrids Research Center at the Korea Institute of Science and Technology (KIST) developed the high-capacity, stretchable lithium-ion battery. The battery was developed by fabricating a structurally stretchable electrode consisting solely of electrode materials and then assembling it with stretchable gel electrolyte and stretchable packaging.

Pagination

- Page 1

- Next page