Graphene transistors could enable ultrasensitive detection of infections

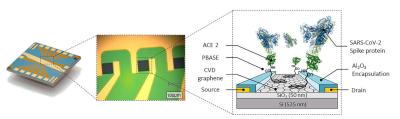

Researchers from Friedrich Schiller University Jena, CNM Technologies, NOXXON Pharma, APTARION Biotech and Radboud University Medical Center have developed graphene field effect transistor (GFET) sensors based on van der Waals (vdW) heterostructures of single-layer graphene layered with a molecular ≈1 nm thick carbon nanomembrane (CNM).

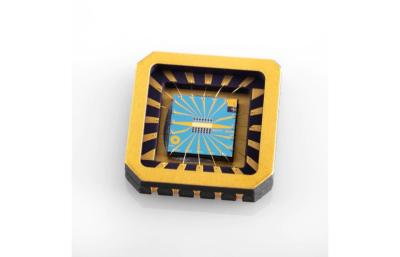

1 / 1Schematic illustration of the fabrication steps of the l-AP/PEG-CNM GFET sensors. Credit: Advanced Materials

The CNM acts as an ultrathin molecular interposer between the graphene channel and the analyte and allows bio-functionalization without impairing the graphene properties including its charge carrier mobility.