Microwaving a graphene composite could improve gas & oil wells

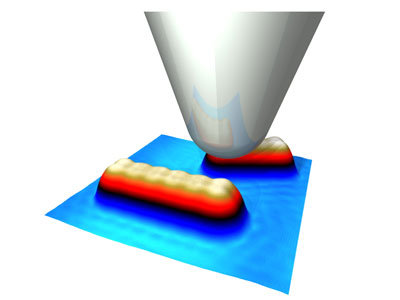

Researchers at Rice University have shown that adding modified graphene nanoribbons to a polymer and then microwaving the mixture appears to reinforce wellbores drilled to extract oil and natural gas, which can make wells more stable and reduce production costs.

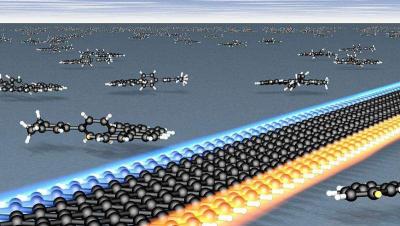

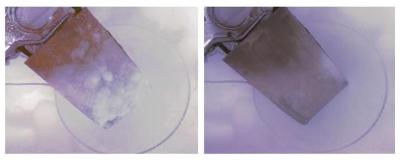

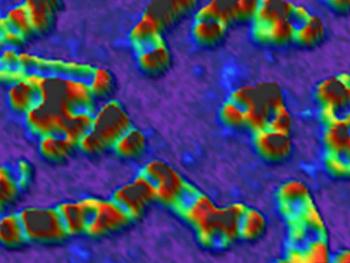

The team combined a small amount of the nanoribbons with an oil-based thermoset polymer. The combination then was cured in place with low-power microwaves emanating from the drill assembly, resulting in the composite plugging microscopic fractures. The combination allowed drilling fluid to seep through and destabilize the walls.