Graphene-Info is happy to give the stage to talented young graphene researchers, especially with such commitment and passion as Roberto Pezone from TU Delft, who has agreed to chat with us and answer a few questions about his background, work and collaboration with the Graphene Flagship.

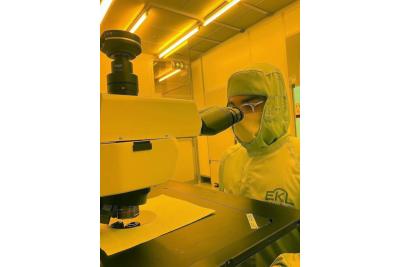

Roberto Pezone checking a wafer at its initial fabrication stages

Q: Thank you for this interview Roberto! Very nice to e-meet you. We know you have been involved with graphene research for some time, can you give us a quick overview of your graphene research interests and projects?

Thank you for the opportunity to discuss my research. Within the Graphene Flagship's Work Package 6 (core 3), my primary focus lies in integrating graphene into sensors, particularly microphones. My main objective is to develop methods that enable the seamless integration of graphene on a wafer-scale while thoroughly exploring the advantages and disadvantages associated with such approaches.

In addition to developing fabrication techniques, I am also highly interested in characterizing the potential of graphene for acoustic devices. This type of research plays a crucial role in bridging the gap between graphene's exceptional properties and its practical utilization in the industry, unlocking higher performance and new sensor concepts.

Q: Your current research is focused on graphene-based microphones. Can you explain how graphene is used in this project? What are your current research achievements and goals?

Our hearing sense is predominantly regulated by the eardrum, also known as the tympanic membrane, which vibrates in response to sound waves. These vibrations are then converted into electrical signals that are transmitted to the brain, allowing us to perceive sound. In the realm of microphone technology, the conventional approach is inspired by this natural concept, where a sensitive vibrating membrane plays a key role. In our research, we explore how graphene can be utilized in this context to revolutionize microphone technology.

In particular, for miniaturized microphones like MEMS (Microelectromechanical Systems) microphones, which are commonly found in portable devices such as smartphones, laptops, and earphones, graphene holds tremendous potential as a substitute for silicon, the conventional material used in these devices. Our research has focused on developing a wafer-scale fabrication method, building upon a transfer-free approach previously developed by Dr. Sten Vollebregt in our group. Using this method, we have successfully fabricated free-standing multi-layer graphene membranes with a thickness of less than 10 nm, achieving a repeatable method with great yield of up to 90% on a silicon 4” wafer. These graphene diaphragms exhibit significantly higher mechanical sensitivity, also called mechanical compliance, compared to silicon-based diaphragms commonly used in the market-available MEMS microphones. Our collaborative efforts with Prof. Peter G. Steeneken, Dr. Sten Vollebregt and Gabriele Baglioni have demonstrated sensitivity levels almost 100 times greater than conventional silicon membranes. Importantly, these achievements have been realized within reduced areas of almost 10 times, paving the way for future compact and powerful devices.

In addition to our research findings, we have also conducted measurements in industry professional setups, collaborating with leading companies in this field.

Our research outcomes have been published in two works:

- https://pubs.acs.org/doi/full/10.1021/acsami.2c03305

- https://pubs.rsc.org/en/content/articlelanding/2023/nr/d2nr05147h

Furthermore, we have recently made significant advancements in our research by upgrading our previous method to a final capacitive architecture. This approach allows us to directly translate the vibrations of the graphene diaphragm into electrical signals, as for current Si-based MEMS microphones. We are excited to share these latest findings, and they will be presented at the upcoming conference, Transducers '23, which will take place next June in Kyoto, Japan. Looking ahead, our goal is to integrate these graphene-based microphone devices into conventional SiP (System-in-Package) technology. By incorporating application-specific integrated circuits (ASICs) for optimized read-out capabilities, we aim to fully explore and understand the benefits and limitations that graphene can bring to microphone technology.

Q: There's much interest in graphene for audio applications. How does your research project and achievements compared to commercial announcement by companies?

To the best of my knowledge, there are currently no companies that have released a commercially available graphene microphone. However, there are several companies, such as Graphaudio, Dirigent Acoustics, Iceni Labs, and Ora Graphene Audio, that are actively exploring graphene acoustic applications. These companies are generating excitement in the industry. It is fascinating to consider how graphene could potentially transform the market, and we look forward to witnessing its integration into various devices.

Their technologies are not widely publicized, making direct comparisons with our own methods and vision difficult. However, we are confident in our approach. Our research project focuses on a wafer-scale bulk-micromachining process-flow that can be adapted with some modifications to standard fabrication lines. This adaptability offers promising opportunities for bridging the gap between research and industry.

There is still much work to be done in thoroughly investigating and optimizing the properties necessary for graphene microphone applications and achieving a final product suitable for mass production with durability. We are actively engaged in ongoing research and development efforts to address these challenges and provide comprehensive answers to these crucial questions.

Q: What can you say regarding working with/at the graphene flagship?

I am delighted to be a part of the Graphene Flagship, as it provides a great opportunity for me as a researcher. Working on a material like graphene, which holds immense promise for various fields in the future, is truly exciting. Being a part of this consortium allows me to collaborate with individuals from diverse backgrounds, each bringing their unique expertise to the table. This vibrant environment fosters great collaborations and facilitates the realization of significant projects.

Every day, I am captivated by the remarkable outputs and breakthroughs coming from the Graphene Flagship community. The consortium constantly produces cutting-edge research, pushing the boundaries of our understanding of graphene and other 2D materials. It serves as the essential core that drives the exploration of the fundamental properties of these materials and their integration into our daily lives.

Q: What do you think of the winding down of the Flagship project this year? How will this affect research institutes, and the industry in Europe?

Indeed, everything in life follows a cycle with a beginning and an end, and the completion of the Graphene Flagship project is no exception. While the winding down of the Flagship project signifies the conclusion of a significant chapter, it's essential to acknowledge the potential challenges that may arise.

One of the potential concerns is the impact on unfinished projects. The completion of the Flagship project may result in a decrease in dedicated support and resources, which could potentially slow down the progress of ongoing research initiatives. Without the same level of concrete support, it may be more challenging to maintain the same momentum and scientific output that was witnessed during the active phase of the project.

However, it's essential to recognize that the Graphene Flagship has laid a strong foundation for European graphene research and development. The collaborations, knowledge exchange, and infrastructure established during these years have equipped research institutes and industry partners with valuable expertise and networks. While the winding down of the Flagship project may present challenges, the accumulated knowledge and resources gained through the initiative can hopefully continue to drive progress in unfinished projects.

Q: Do you have any tips or suggestions for young researchers starting out with graphene research?

In research, being motivated and passionate about your goal is essential, just as it is for any researcher. Graphene's remarkable properties enable its application in various fields and offer opportunities to explore new and unknown phenomena. Its versatility makes it suitable for a wide range of research interests. To excel in this field, it is crucial to stay constantly updated with the latest advancements and breakthroughs. This knowledge keeps you informed, allowing you to work efficiently and with precision, particularly when focusing on concrete applications.

Q: Where do you see graphene making the most impact in 3-5 years?

In the next 3-5 years, graphene is expected to make a significant impact in several areas. It holds great potential in electronics and optoelectronics, offering faster and more efficient devices like flexible displays and high-speed transistors. Graphene-based energy storage solutions may lead to improved battery performance and faster charging. Sensors and detectors utilizing graphene could revolutionize environmental monitoring and healthcare. Graphene's integration into composite materials may enhance their strength and durability, benefiting industries like aerospace and automotive. In the field of biomedicine, graphene holds promise for drug delivery, tissue engineering, and biosensors. These areas represent exciting opportunities where graphene's unique properties can drive innovation and advancements in the near future.

Thank you, Roberto, and good luck with your work!

While it is fine to put a…

While it is fine to put a spotlight on a scientist, he does not seem to have a bigger picture of graphene and applications, stating standard phrases that he has seen in media. Everyone is only showing some good data that they measured, but not really saying that it either failed many other necessary specifications, or how it compared to hundreds of other alternatives. Almost always those alternative materials are better if ranked in multiple parameters.

There will not be flexible displays based on graphene, in fact companies like LG produced roll-to-roll large area CVD graphene for displays, but no-one is using it for that. It's not conductive enough. People have to add some "dopant" for it to be more conductive, but they the display is not transparent or orange or patchy. There will not be high-speed transitors as graphene is not a semiconductor, and the whole era of trying to use it for this has long passed. Some spurious market reports that it could replace silicon and establish a $70bn market are complete nonsense. Without any other example of this high-quality graphene, the researcher switched to poweder graphite applications and buzzwords, where these powders can bring marginal benefits even after billions of funding has been pumped into this research.

There is a handful of niche applications where graphene could be transformative, but these are quite complex and specific, know by a selection of experts in the field with 10+ years of experience.

It is true that currently we…

It is true that currently we do not see wide adoption of graphene, although there are some very successful applications, many of which are not public or not of 'interest'.

But materials science is difficult, It took CNTs many years before the first major application, but it finally found one (batteries) and we believe graphene will find many useful and real applications, but it may take more years before we realize that.