Graphene for the mobile industry

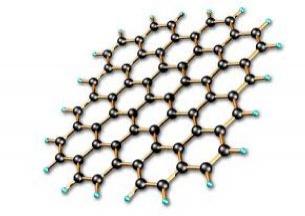

What is graphene?

Graphene is a two dimensional layer of carbon atoms, arranged in the form of a honeycomb lattice. It is touted as a âmiracle materialâ because it is endowed with an abundance of astonishing traits - this thin, one atom thick substance is the lightest, strongest, thinnest material known to man, as well as the best heat and electricity conductor ever discovered - and the list does not end there. Graphene is the subject of relentless research and is thought to be able to revolutionize whole industries, as researchers work on many different kinds of graphene-based materials - each one with unique qualities and purpose.

Graphene for the mobile industry

The significant body of work on various properties and applications of graphene shows that its potential to disrupt entire industries is enormous. In the field of mobile technology, graphene applications could be varied and touch everything from transparent flexible screens to next-gen batteries which could last much longer and charge faster than any current technology, through durable phone casings and extremely powerful processors.

Despite grapheneâs amazing potential, there are still quite a few challenges to overcome before applications become commercialized and commonplace. Production costs, volume manufacturing, standardization and market awareness and acceptance are just some of the key challenges that need to be addressed, and it will probably take some time and efforts before graphene can truly live up to the hype.

The MWC 2016, the world's largest event for the mobile industry held in Barcelona, Spain, will feature an entire pavilion dedicated to graphene in regards to the mobile world. This exciting precedent emphasizes the growing attention that graphene is receiving in the technological world and the recognition of its ability to become increasingly important in the future.

Graphene and batteries

Conventional battery electrode materials can be significantly improved when enhanced with graphene. Graphene can make batteries that are light, durable and suitable for high capacity energy storage, as well as shorten charging times. It will extend the batteryâs life-time, and add conductivity without requiring the relatively large amount of carbon that is used in conventional batteries.

Graphene can improve such battery attributes as energy density and form in various ways. Li-ion batteries can be enhanced by introducing graphene to the batteryâs anode and capitalizing on the materialâs conductivity and large surface area traits to achieve morphological optimization and performance. LFP ( Lithium Iron Phosphate) batteries, a kind of rechargeable Li-ion battery, have a lower energy density than other Li-ion batteries but a higher power density. Enhancing LFP cathodes with graphene allows the batteries to be lightweight, charge much faster than Li-ion batteries and have a greater capacity than conventional LFP batteries.

Many see next-gen batteries as moving away from electrochemical cells towards supercapacitors, and a combined use of graphene batteries and supercapacitors could yield amazing results. Supercapacitors store energy in an electric field instead of a controlled chemical reaction. Supercapacitors display quicker charging times and are more durable and consistent across a wider temperature range compared to batteries.

Graphene-enhanced displays

Given grapheneâs conductivity, flexibility and transparency, displays are a natural choice of path for graphene use. The three most popular areas are graphene-based conductive wires for transparent touch panels, display backplanes and transparent electrodes for OLEDs.

Currently, most touch panels (used mostly in mobile phones and tablets) use indium tin oxide (ITO) that is conductive and transparent, but in limited supply and also brittle (thus not suitable for flexible panels), so companies are looking for alternatives. Graphene can be an excellent candidate for replacing ITO, especially in flexible displays. Still, despite the fact that the display market indeed seems like a natural fit for graphene and that it is one of the first applications to have been commercialized (especially in China), several other technologies exist, like silver mesh and silver nanowires, that are more advanced and seem to be better suited than graphene for this specific application.

ITO is also used today in displays as a transparent electrode (cathode in bottom-emitting displays or anode in top-emission displays). Again, as in touch panels, it is possible to replace the ITO cathode / anode with a graphene-based one.

Graphene may also be used to produce a display backplane. The backplane is the driver (or electronics) that is used to control which pixels are on and which are off in a display. Currently most displays (whether LCD, e-paper or OLED) use silicon or Oxide-Metal TFT backplanes. Graphene is highly conductive, but it has no bandgap â so itâs not suitable for a backplane material. However, it is possible to introduce a bandgap to graphene. Other next-gen backplane materials include graphene-like 2D materials that do have a bandgap (such as MoS2).

Chips and processors

Grapheneâs excellent conductivity, along with other properties, makes it particularly exciting for use in various computing technologies to improve their speed and efficiency. More and more research is done in this field, that shows that graphene and other 2D materials will eventually become the ânew siliconâ. In addition to improving the speed and efficiency of mobile devices, graphene may also enable light and slim devices like smartwatches, wearables and other accessories.

Graphene does not have a bandgap, which means that it cannot be readily used to make transistors. However, there are many ways to open a bandgap in grapheneâby using graphene ribbons, doping it, using bi-layer graphene and more. It is also possible to build logic gates using graphene based on negative resistance, without opening a bandgap.

Recent years have brought massive investments in graphene-based electronics research, at universities and research institutes, as well as in large corporations like IBM, Intel and Samsung. The electronics may present a huge opportunity for graphene use, but in any case, the time frame is of at least 5-10 years before any graphene-based electronics reach commercialization.

Graphene can also be used as a conductive material in electronic devices, besides transistorsâfor example making fast electron-light interconnectors between electronic devices and light wave devices (such as fiber optics and photonic chips).

Graphene and sensors

Sensors detect events that occur in the physical environment (like light, heat, motion, moisture, pressure, and more), and respond with an output. Graphene and sensors are a natural combination, as grapheneâs large surface-to-volume ratio, unique optical properties, excellent electrical conductivity, high carrier mobility and density, high thermal conductivity and many other attributes can be greatly beneficial for sensor functions.

Modern mobile phones are loaded with a myriad of sensors. Accelerometers detect the orientation of the phone and gyroscopes add an additional dimension to the information supplied by the accelerometer by tracking rotation or twist; Digital compasses are usually based on a sensor called magnetometer that provides mobile phones with a simple orientation in relation to the Earth's magnetic field, Barometers assist the GPS chip inside the device by delivering altitude data, and of course there are also sensors for fingerprints, light and proximity sensors, and many more.

Graphene will enable sensors that are smaller and lighter - providing endless design possibilities. They will also be more sensitive and able to detect smaller changes in matter, work more quickly and eventually even be less expensive than traditional sensors.

Thermal management

Graphene is the world's best heat conductor, which enables many interesting heat management applications. Among these are heat conducting coatings, heat dissipation films and sinks and in addition, all sorts of novel uses and products that take advantage of graphene's unique properties. Such thermal management materials are critical for current and next generation devices

Graphene has many advantages to offer to this substantial market, and the technology is quite mature. Some products are already entering the market, like thermal foils that can be used for the technology beneath devices' screens to conduct heat away from internal electronic components and batteries to help maintain optimal performance.

Graphene-enhanced composite materials

Composite materials are materials formed by combining two or more materials with different properties to produce an end material with unique characteristics. Composite materials have many advantages, as they can be made to be lightweight, strong, corrosion and heat resistant, flexible, transparent and more according to specific needs. They are quite ubiquitous, used in many industries, like aerospace, sports equipment, automotive components, building materials, medical utilities and more.

Grapheneâs myriad of attributes can be used to make extraordinary composites. The presence of graphene can enhance the conductivity and strength of bulk materials and help create composites with superior qualities. Graphene can also be added to metals, polymers and ceramics to create composites that are conductive and resistant to heat and pressure. In mobile phones, graphene composites can be used to make light, flexible and durable casings.

Printed antennae and conductive inks

Conductive inks contain components that provide the function of conductivity. Many conductive inks are offered on the market, to meet the demands of many applications: electronics, sensors, antennae, touch screens, printed heaters and more. Thanks to its high charge carrier mobility, superlative thermal and chemical stability and intrinsic flexibility, graphene is a natural choice for use in inks, for applications like thin-film transistors (TFTs) and printed electronics. Graphene inks expand the possibilities for applications such as printed electronics, specifically printed antennae for mobile phones.