First Graphene and Halocell enter agreement to supply graphene for perovskite solar cells

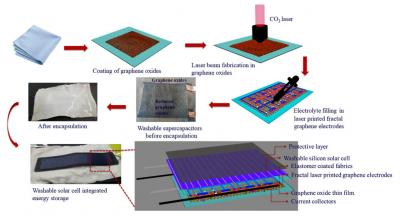

First Graphene has secured an agreement with Halocell Energy to supply graphene for the manufacture of perovskite solar cells.

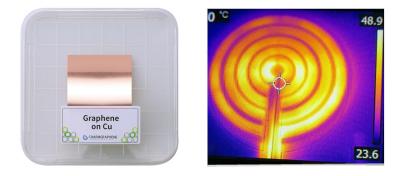

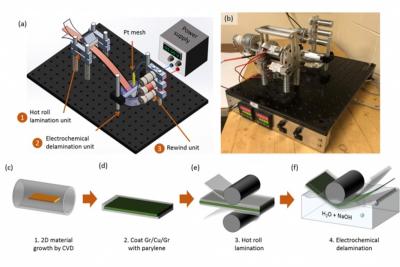

The initial two-year agreement will result in First Graphene providing its PureGRAPH material to Halocell for use as a high-performing coating for perovskite solar cells. By incorporating PureGRAPH into its products, Halocell Energy hopes to expedite its manufacturing process and enhance light absorbing performance, which will enable the company to scale up commercial production to meet demand.