Haydale income in H2 2015 rose 63%, net loss was £1.9 million

Haydale announced financial results for the second half of 2015 (H1 FY2016). Total income rose to £800,000 (up 63% from the second half of 2014) and the net loss after tax was £1.9 million (up from £1.5 million in H2 2014).

Haydale announced financial results for the second half of 2015 (H1 FY2016). Total income rose to £800,000 (up 63% from the second half of 2014) and the net loss after tax was £1.9 million (up from £1.5 million in H2 2014).

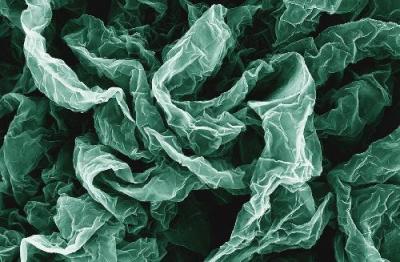

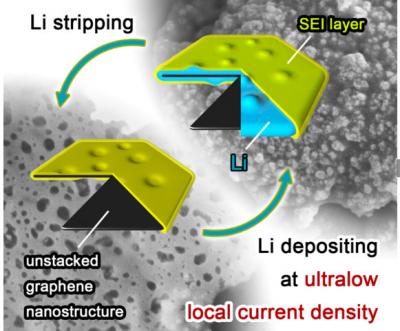

Haydale also reports significant (£500,000) R&D investment particularly in respect of graphene enhanced resins for the composite markets. At the end of December 2015, cash at hand was £5.0 million (up from £2.0 million at the end of June 2014 following Haydale's recent fund raising).