CVD Equipment Corporation (a US-based company) offers a variety of process and support equipment for both R&D and production facilities. CVD Equipment offers graphene production systems.

In August 2013 CVD announced it will jointly develop graphene-based Li-Ion battery electrodes with Graphene Batteries.

CVD Equipment is a public company, trading in the NASDAQ (ticker: CVV).

355 South Technology Drive

Central Islip, NY 11722

United States

New graphene-based coating developed for the protection of paintings

A team of researchers from the Institute of Chemical Engineering Sciences of Foundation for Research and Technology-Hellas (FORTH/ ICE-HT), the Department of Chemical Engineering of the University of Patras, and the Center for Colloid and Surface Science (CSGI) of the University of Florence, led by Professor Costas Galiotis, set out to use 'graphene veils' for the protection of paintings against environmental degradation.

The exposure of colors used in artworks to ultraviolet (UV) and visible light in the presence of oxidizing agents, triggers color degradation, fading and yellowing. These degradation mechanisms can lead to irreversible alteration of artworks, which consist of a valuable heritage for humankind. Currently used protective varnishes and coatings are often problematic, as their removal requires the use of solvents, which can adversely affect the underlying work surface.

Versarien acquires CVD assets and IP from Hanwha Aerospace and enters into a subscription agreement

Versarien has announced that it has agreed to acquire certain graphene production related assets and intellectual property from South Korea based Hanwha Aerospace, for (the equivalent to) £4.34 million (around USD$5.8 million).

Versarien has announced that it has agreed to acquire certain graphene production related assets and intellectual property from South Korea based Hanwha Aerospace, for (the equivalent to) £4.34 million (around USD$5.8 million).

In addition, the Company has entered into a subscription agreement with Lanstead Capital Investors LP to subscribe for raising gross proceeds of £3.50 million (around USD$4.7 million), the proceeds of which will be used for an additional sharing agreement with Lanstead.

CrayoNano orders Veeco's MOCVD system for nanowire on graphene growth

Veeco Instruments, a U.S-based process equipment maker, recently announced that CrayoNano, a research company for ultraviolet short wavelength light emitting diodes (UV-C LEDs), has ordered the Propel Power Gallium Nitride (GaN) Metal Organic Chemical Vapor Deposition (MOCVD) System. CrayoNano will use the system to grow semiconductor nanowires on graphene for water disinfection, air purification, food processing and life science applications.

CrayoNano is a nanotechnology company specializing in developing optoelectronic devices based on semiconductor nanowires on graphene substrates. The Company originates from several years of research at the Norwegian University of Science and Technology (NTNU) in Trondheim. The Company aims to transform the UV LED marketwith a technology based on a unique method of growing nanowires on graphene.

CalBattery announces scaling-up production of its high capacity anode material

CalBattery, the U.S-based developer of a Silicon-Graphene (SiGr) composite anode material for li-ion batteries, recently announced that it has successfully scaled-up its new fluidized bed chemical vapor deposition process and is producing commercial quality and quantities of its breakthrough high capacity silicon composite anode material for use in li-ion batteries.

CalBattery, the U.S-based developer of a Silicon-Graphene (SiGr) composite anode material for li-ion batteries, recently announced that it has successfully scaled-up its new fluidized bed chemical vapor deposition process and is producing commercial quality and quantities of its breakthrough high capacity silicon composite anode material for use in li-ion batteries.

Over the past 5 years CalBattery’s team has worked with over thirty engineering groups to develop, build, and optimize a new type of fluidized bed chemical vapor deposition reactor capable of producing novel industry leading silicon composite lithium battery anode materials that can be specially engineered to incorporate between 10% -50% silicon with limited swelling and good cycle life compared to other LIB silicon anode materials used today.

Graphenea updates on progress of plans for mass production of high quality graphene

The Spain-based Graphenea recently announced that preparations are on track for mass production of 200 mm (8) diameter high quality graphene on Si/SiO2 wafers. Last week cleanroom components arrived to be assembled in a new production space at the company's location in San Sebastian. Production of 200 mm graphene on a new chemical vapor deposition system is expected to be up and running at the beginning of 2017.

The Spain-based Graphenea recently announced that preparations are on track for mass production of 200 mm (8) diameter high quality graphene on Si/SiO2 wafers. Last week cleanroom components arrived to be assembled in a new production space at the company's location in San Sebastian. Production of 200 mm graphene on a new chemical vapor deposition system is expected to be up and running at the beginning of 2017.

The investment in the new lab will increase the company’s production capacity and quality of graphene wafers. The new addition will represent a tenfold expansion of Graphenea's production space, where it currently routinely manufactures high quality graphene with a diameter of 100 mm (4). The production capacity will increase 20-fold with the addition of the new line, to produce 4, 6, and 8 wafers as standard.

Aixtron takes part in “HEA2D” project to investigate the production, qualities, and applications of 2D nanomaterials

Aixtron, a leading provider of deposition equipment, is working together with five partners in the “HEA2D” project to investigate the production, qualities, and applications of 2D nanomaterials.

Aixtron, a leading provider of deposition equipment, is working together with five partners in the “HEA2D” project to investigate the production, qualities, and applications of 2D nanomaterials.

The joint project is now researching an end-to-end processing chain consisting of various deposition processes for 2D materials, processes for transfer onto plastic foils, and mass integration into plastics components. AIXTRON’s partners for implementing systems technology and integrating materials into plastic molded parts are the Fraunhofer Institute for Production Technology (IPT), Coatema Coating Machinery, and Kunststoff-Institut Lüdenscheid (K.I.M.W.). This work is being supported in terms of nano-analytics and the development of prototype components by the Institutes of “Electronic Materials and Nanostructures” (University of Duisburg-Essen) and “Graphene-based Nanotechnology” (University of Siegen).

The Italian CNR-IMM orders an AIXTRON BM Pro system

Aixtron, a leading global provider of deposition equipment to the semiconductor industry, has announced that the Institute for Microelectronics and Microsystems of the Italian National Research Council (CNR-IMM) in Catania, Italy, has purchased a BM Pro system in a 6-inch wafer configuration.

The equipment will be used to produce carbon nanotubes and graphene for the WATER (Winning Applications of Nano Technology for Resolutive Hydropurification) project, focused on the use of nanomaterials for water purification. In particular, the research is investigating carbon nanostructures, such as nanotubes and graphene, that have turned out to be the most promising nanomaterials for such applications.

New facility for graphene manufacture and R&D launched by The University of Granada

The University of Granada in Spain has launched the Graphene and 2D Semiconductors Laboratory, said to be one of the most complete public laboratories devoted to the manufacture and electric and structural characterization of graphene in Europe. This laboratory is supposedly comparable to that of the University of Cambridge (United Kingdom) or the one in the University of Stanford (United States).

The new facilities are located in the UGR Research Centre for Information Technology and Communication. With an investment of more than half a million euros, the new laboratory is devoted to the manufacture of all kinds and forms of graphene as well as the development of new graphene-based systems for electronic applications which include biosensors, electronic nanodevices for IoT (Internet of Things) applications, and flexible electronics, in addition to wearable devices.

NRL and University College purchase Oxford Instruments' CVD equipment

The U.S Naval Research Laboratory (NRL) and University College, London, recently purchased Oxford Instruments' plasma processing Nanofab equipment using CVD, PECVD and ICPCVD techniques.

The Nanofab enables the fabrication of nanostructured materials such as graphene, carbon nanotubes and other 1D and 2D nanomaterials. It combines several essential features for high performance growth such as a high temperature heater capable of processing up to 200 mm wafers, shower head technology, automatic load lock for wafer handling as well as flexible options for liquid/solid precursor delivery.

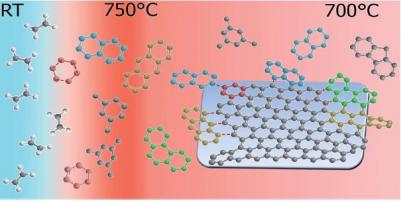

Preheating gas precursors enhances CVD graphene production

Researchers from Israel's Bar Ilan University discovered that preheating the gas precursors in atmospheric-pressure CVD graphene production results in 100% reproducibility, and higher quality graphene sheets.

The researchers say that the graphene produced in the new method required a lower processing temperature and exhibited 50% less defects compared to graphene made without gas preheating. In addition, all experiments (100% reproducibility) performed with gas heating led to "acceptable quality" graphene - compared to only 15% of the experiments performed without gas preheating.

Pagination

- Page 1

- Next page