NanoEDGE: German-Israeli collaboration to develop wearable electronics for mental disorder diagnosis and functional restoration

The NanoEDGE BMBF-Project, coordinated by the Fraunhofer Institute for Biomedical Engineering IBMT, aims at the development of a graphene-based ink for inkjet printing and a scalable printing process as well as a resource-efficient process chain for the production of electrodes for direct skin contact.

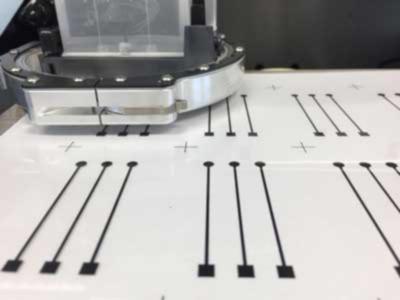

Printed test electrodes in the NanoEDGE project

Printed test electrodes in the NanoEDGE project

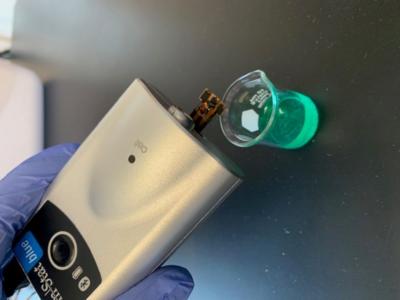

The development of a graphene-based ink is based on a commercial graphene ink. Ink modification was necessary to make it printable. Ethanol is added to avoid bubbles and to decrease the surface tension of the ink. Carbon nanoparticles are added to improve abrasion resistance of printed structures. A surfactant is added to improve printability and to increase the conductivity and surface smoothness of printed structures.