Researchers at MIT and Harvard University fabricated nanoscrolls made from graphene oxide flakes for water purification applications, at a much lower cost than that of graphene membranes. The team was able to control the dimensions of each nanoscroll, using both low- and high-frequency ultrasonic techniques.

The researchers say that these nanoscrolls could also be used as ultralight chemical sensors, drug delivery vehicles, and hydrogen storage platforms, in addition to water filters. Also, the ability to tune the dimensions of these architectures may open a window to industry, in combination with the more affordable production costs.

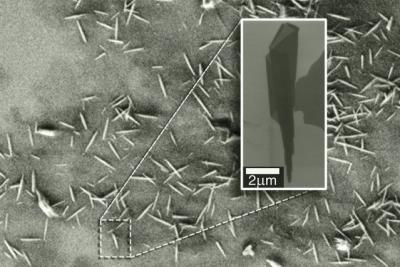

The team first used a common technique called the Hummers’ method to separate graphite flakes into individual layers of graphene oxide. They then placed the graphene oxide flakes in solution and stimulated the flakes to curl into scrolls, using two similar approaches: a low-frequency tip-sonicator, and a high-frequency custom reactor. They applied both techniques to solutions of graphene oxide flakes and observed similar effects: The bubbles that were created in solution eventually collapsed, releasing energy that caused the flakes to spontaneously curl into scrolls. The researchers found they could tune the dimensions of the scrolls by varying the treatment duration and the frequency of the ultrasonic waves. Higher frequencies and shorter treatments did not lead to significant damage of the graphene oxide flakes and produced larger scrolls, while low frequencies and longer treatment times tended to cleave flakes apart and create smaller scrolls.

While the group’s initial experiments turned a relatively low number of flakes (about 10%) into scrolls, they say both techniques may be optimized to produce higher yields. If they can be scaled up, the techniques can be compatible with existing industrial processes, particularly for water purification.