What is a solar panel?

Solar panel electricity systems, also known as solar photovoltaics (PV), capture the sunâs energy (photons) and convert it into electricity. PV cells are made from layers of semiconducting material, and produce an electric field across the layers when exposed to sunlight. When light reaches the cell, some of it is absorbed into the semiconducting material and causes electrons to break loose and flow. This flow of electrons is an electric current, that can be drawn out and used for powering outside devices. This current, along with the cellâs voltage (a result of built-in electric fields), define the power that the solar cell is capable of producing. It is worth mentioning that a PV cell can produce electricity without direct sunlight, but more sunshine equals more electricity.

A module, or panel, is a group of cells connected electrically and packaged together. several panels can also form an array, which can provide more electricity and be used for powering larger instruments and devices.

Different kinds of Solar cells

Solar cells are roughly divided into three categories: Monocrystalline, Polycrystalline and Thin Film. Most of the worldâs PVs are based on a variation of silicon. The purity of the silicon, or the more perfectly aligned silicon molecules are, affects how good it will be at converting solar energy. Monocrystalline solar cells (Mono-Si, or single-crystal-Si) go through a process of cutting cylindrical ingots to make silicon wafers, which gives the panels their characteristic look. They have external even coloring that suggests high-purity silicon, thus having the highest efficiency rates (typically 15-20%). They are also space efficient (their efficiency allows them to be small) and live longer than other kinds of solar panels. Alas, they are more expensive than other kinds and tend to be damaged by external dirt or snow.

Polycrystalline silicon (p-Si or mc-Si) solar cells do not go through the abovementioned process, and so are simpler and cost less than Monocrystalline ones. Their typical efficiency is 13-16%, due to lower silicon purity. They are also bigger and take up more space.

Thin-Film solar cells (TFSC), are made by depositing one or several thin layers of photovoltaic material onto a substrate. Different types of TFSCs are categorized by which photovoltaic material is deposited onto the substrate: Amorphous silicon (a-Si), cadmium telluride (CdTe), copper indium gallium selenide (CIS/CIGS), polymer solar panels and organic photovoltaic cells (OPC). Thin-film modules have reached efficiencies of 7-13%. Their mass production is simple, they can be made flexible and are potentially cheaper to manufacture than crystalline-based solar cells. They do, however, take up a lot of space (hampering their use in residential applications) and tend to degrade faster than crystalline solar panels.

Solar power advantages and disadvantages

Solar power is free and infinite, and solar energy use indeed has major advantages. It is an eco-friendly, sustainable way of energy production. Solar energy systems today are also much cheaper than they were 20 years ago, and save money in electricity expenses. In addition, it is a much environmentally cleaner form of energy production that helps reduce global warming and coal pollution. It does not waste water like coal and nuclear power plants and is also considered to be a form of energy that is much safer for use.

Although solar power production is widely considered to be a positive thing, some downsides require mentioning. The initial cost of purchasing and installing solar panels can be substantial, despite widespread government subsidy programs and tax initiatives. Sun exposure is critical and so location plays a significant role in the generation of electricity. Areas that are cloudy or foggy for long periods of time will produce much less electricity. Other commonly argues disadvantages regard insufficiency of produced electricity and reliability issues.

Solar power applications

Common solar energy applications include various residential uses such as solar lighting, heating and ventilation systems. Many small appliances utilize solar energy for operation, like calculators, scales, toys and more. Agriculture and horticulture also employ solar energy for the operation of different aids like water pumps and crop drying machines. The field of transportation has been interested in solar powered vehicles for many years, including cars, planes and boats that are vigorously researched and developed. Solar energy also has various industrial applications, ranging from powering remote locations as well as space and satellite systems, to powering transportation signals, lighthouses, offshore navigation systems and many more.

Solar technologies are vigorously researched, aiming to lower costs and improve existing products as well as integrate PV systems in innovative products like PV-powered curtains, clothes and laptop cases.

Graphene and solar panels

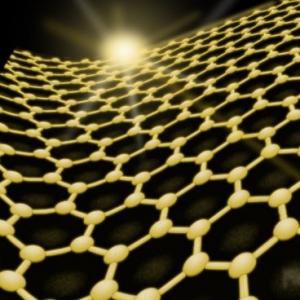

Graphene is made of a single layer of carbon atoms that are bonded together in a repeating pattern of hexagons. It is a 2 dimensional material with amazing characteristics, which grant it the title âwonder materialâ. It is extremely strong and almost entirely transparent and also astonishingly conductive and flexible. Graphene is made of carbon, which is abundant, and can be a relatively inexpensive material. Graphene has a seemingly endless potential for improving existing products as well as inspiring new ones.

Solar cells require materials that are conductive and allow light to get through, thus benefiting from graphene's superb conductivity and transparency. Graphene is indeed a great conductor, but it is not very good at collecting the electrical current produced inside the solar cell. Hence, researchers are looking for appropriate ways to modify graphene for this purpose. Graphene Oxide (GO), for example, is less conductive but more transparent and a better charge collector which can be useful for solar panels.

The conductive Indium Tin Oxide (ITO) is used with a non-conductive glass layer as the transparent electrodes in most organic solar panels to achieve these goals, but ITO is rare, brittle and makes solar panels expensive. Many researches focus on graphene as a replacement for ITO in transparent electrodes of OPVs. Others search for ways of utilizing graphene in improving overall performance of photovoltaic devices, mainly OPVs, as well as in electrodes, active layers, interfacial layers and electron acceptors.

Commercialization efforts

While graphene-based solar cells are not currently commercially available, some efforts are bearing fruit in regards to the use of graphene in auxiliary aspects of PV. One such example is ZNShine Solar's G12 evolution era series - comprised of a 12-busbar graphene module, 5-busbar graphene module and double-glass graphene module. According to reports, the application of ZS's graphene film layer increases light transmission performance of the glass itself. In addition, Znshine Solar's modules are self-cleaning. In July 2018, ZNShine Solar won the bid to provide 37.5MW of PV modules to Bharat Heavy Electricals Limited (BHEL), India's largest power generation equipment manufacturer. According to the contract, 10% of the shipment will be graphene-coated solar panels. In June 2019, Znshine Solar announced signing a 100MW graphene-enhanced solar module supply agreement with UAE's Etihad Energy services.

Further reading

The latest graphene solar news:

2D perovskites may rival graphene in PV applications

Department of Energy (DoE) funded researchers investigated the electronic properties of 2D hybrid organic-inorganic perovskite sheets, as an alternative to graphene and other materials. The researchers reported that such perovskites could rival graphene in PV applications, since the 2D crystals exhibited efficient photoluminescence, were easier to grow than graphene and it's possible to dope it to make the various varieties of ionic semiconductors needed to beat other 2D materials with tunable electronic/photonic properties.

Scientists created these new forms of hybrid organic-inorganic perovskites in atomically thin 2D sheets and first showed how they hold promise as semiconductor materials for photovoltaic applications. Next they showed how they could serve as an alternative to other 2D semiconductors that are widely studied as potential successors to silicon in future electronic devices.

Graphene quantum dots and TiO2 exhibit fascinating light harvesting capabilities

Researchers at Australia's Griffith University have discovered a fascinating mechanism, that may allow the design of a new class of composite materials for light harvesting and optoelectronics. The team has found a quantum-confined bandgap narrowing mechanism, where UV absorption of the graphene quantum dots and TiO2 nanoparticles can easily be extended into the visible light range.

According to the scientists, real life application of this would be high efficiency paintable solar cells and water purification using sun light. In addition, the team states that "this mechanism can be extremely significant for light harvesting. What's more important is we've come up with an easy way to achieve that, to make a UV absorbing material to become a visible light absorber by narrowing the bandgap."

Talga outlines plans for graphene products

Talga Resources has outlined its updated commercialization strategy. It is seeking to unlock early commercialization opportunities based on the production of four specific graphene products for use within targeted industrial markets. The development of these product lines is in addition to the supply of raw graphene and graphite materials which has been the Company’s focus to date.

Talga Resources has outlined its updated commercialization strategy. It is seeking to unlock early commercialization opportunities based on the production of four specific graphene products for use within targeted industrial markets. The development of these product lines is in addition to the supply of raw graphene and graphite materials which has been the Company’s focus to date.

The new strategy is reportedly a progression made possible by the growth of Talga’s pilot plant facility in Germany. Recent equipment scale up and a significant boost to the Company’s technical team enables this new ‘applied products’ capability and expedited path to associated sources of revenue.

Graphene quantum dots to help improve silicon solar cells' efficiency

Researchers from KAUST have found that graphene quantum dots could expand the usable spectral region of light in silicon solar cells to boost their efficiency and provide a more cost-effective way for energy production.

![]()

Graphene quantum dots are small flakes of graphene that are useful because of their interaction with light. One of these interactions is optical downconversion, which is a process that transforms light of high energies into lower energy (for example, from the ultraviolet to the visible). Silicon absorbs light very efficiently in the visible part of the spectrum, and therefore appears black. However, the absorption strength of silicon for ultraviolet light is much smaller, meaning that less of this light is absorbed, reducing the efficiency of solar cells in that part of the spectrum. One way around t this problem is the downconversion of ultraviolet light to energies where silicon is a more efficient absorber.

Graphene nanoplatelets to solve a major DSSC catalyst problem

Researchers at UNIST in Korea may have overcome the problem of carbon-based electrocatalysts for dye-sensitized solar cells with their new catalyst made from edge-selenated graphene nanoplatelets.

DSSCs consist of a dye-coated titanium oxide photoanode, an electrolyte and a counter electrode (CE). Currently, the most widely used electrolytes in DSSCs are iodide/triode ones, and the most common CE is an optically transparent thin film of platinum (Pt) nanoparticles on fluorine-doped tin oxide (Pt-FTO). While Pt-based materials are among the most efficient CEs, Pt is an expensive precious metal that is in short supply. That is why researchers are constantly looking for alternative CE materials and the best candidates so far appear to be carbon-based. Such materials include carbon nanotubes, porous carbon, carbon spheres, active carbon and graphene. A major problem, however, with carbon-based CEs is that they are active enough in Co(II)/Co(III) electrolytes (and have a high PCE, here), but not sufficiently so in I-/I3- electrolytes.

CealTech to start high-volume, high-quality graphene production

CealTech aims to become a leading global producer of high volume, high quality graphene, ultra-fine graphite and fine graphite. Production will be done by CealTech's independently-developed FORZA 3D graphene production unit (patent pending).

The FORZA prototype unit is currently under development and should be ready for operation by October 2016. CealTech's daily single layer graphene production capabilities starting October 2016 will be 1600m2, and are planned to grow to 150,000 m2 starting 2020.

Graphene-enhanced solar cells use rain to produce electricity

Researchers at the Ocean University of China in Qingdao and Yunnan Normal University in Kunming developed a highly efficient dye-sensitized solar cell coated with a film of graphene, that makes for an all-weather solar cell that is triggered by both sunlight and raindrops. The results of this study may help eliminate a major disadvantage of solar cells - the fact that they produce no power when it's raining.

The researchers used graphene electrodes to obtain power from the impact of raindrops. Raindrops are not pure water, as they contain salts that dissociate into positive and negative ions. The positively charged ions, including sodium, calcium, and ammonium ions, can bind to the graphene surface. At the point of contact between the raindrop and the graphene, the water becomes enriched with positive ions and the graphene becomes enriched in delocalized electrons. This results in a double-layer made of electrons and positively charged ions, a feature known as a pseudocapacitor. The difference in potential associated with this phenomenon is sufficient to produce a voltage and current.

Chalmers University to collaborate with Ethiopian university on graphene-based composites for solar applications

A research group at the Swedish Chalmers University will collaborate with a group from Addis Ababa University, Ethiopia, on the synthesis and characterization of graphene-polymer composites for solar cell applications. The collaborative project will be funded by the Swedish Research Council through the motto Swedish Research Links, and continues 20 years of collaboration between the two universities.

The role of the polymer will be to harvest the energy from the sun, with graphene as the conductive part of the solar cell. Today, commonly used materials for conduction are fullerenes which, like graphene, are a kind of crystallized carbon. The problem with fullerenes, however, is that they are expensive and also are not stable enough to work efficiently in solar cells.

Grafoid enters agreement with Xiamen Tungsten to develop graphene-based applications in China

Grafoid has announced the signing of a Memorandum of Understanding (MOU) with Xiamen Tungsten of Xiamen, China, for the establishment of a strategic joint venture partnership. The agreement establishes terms for Xiamen's acquisition of up to a 20% equity position in Grafoid through the purchase of common shares - including Grafoid common shares currently held by Grafoid's affiliate, Focus Graphite, an advanced Canadian graphite mining exploration and development company.

Grafoid has announced the signing of a Memorandum of Understanding (MOU) with Xiamen Tungsten of Xiamen, China, for the establishment of a strategic joint venture partnership. The agreement establishes terms for Xiamen's acquisition of up to a 20% equity position in Grafoid through the purchase of common shares - including Grafoid common shares currently held by Grafoid's affiliate, Focus Graphite, an advanced Canadian graphite mining exploration and development company.

Focus Graphite currently holds 7.9 million Grafoid shares, and according to the MOU Xiamen can purchase up to 7 million shares from Grafoid. Seems like Focus Graphite does not want to remain a major shareholder in Grafoid - although the two companies are still linked by a 10-year offtake agreement.

Project GRASS demonstrates graphene-based sensors and solar cells

Project GRASS aims to achieve on-the-field design, development, testing and validating of an innovative prototype of Graphene-Related Node for a Wireless Sensors Network, to be used as autonomous systems for Environmental Monitoring in different areas. The sensor is based on graphene that makes it very energy efficient, which is a major advantage in such components that need to be numerous and work continuously.

The project, along with all of its partners, are members of the Graphene Flagship, and at MWC 2016 we visited their stand and saw their graphene-based NO2 sensor, that as opposed to conventional sensors (that require continuous heating), needs no heating but does require UV light.

Pagination

- Previous page

- Page 7

- Next page