FlexEnable details their graphene OTFT goals

UK-based FlexEnable was spun-off from Plastic Logic in February 2015 with an aim to further develop and commercialize the company’s technology platform for organic thin film transistor (OTFT) arrays for flexible displays and ubiquitous sensing. Last month FlexEnable joined the graphene flagship, and announced plans to develop new use cases for graphene in flexible electronics.

I talked briefly to Mike Banach, FlexEnable's Technical Director, and he explained the company's graphene plans and goals. FlexEnable is not a material company - they do not aim to develop and produce graphene material. The define themselves as a applied process technology - what we call a graphene application developer, focused on the flexible electronics market.

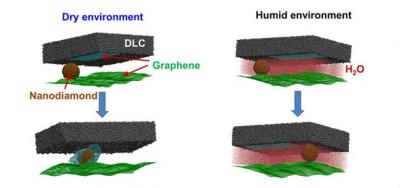

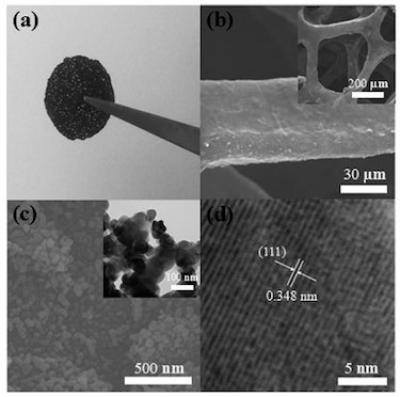

Graphene and diamonds work together to achieve macro-scale superlubricity

Scientists at the US-based Argonne National Laboratory demonstrated a method that reduces friction between two surfaces to almost zero on macroscopic scales, achieving superlubricity. It was done by combining nanodiamonds with sheets of graphene, which curl around the nanodiamonds to form ‘nanoscrolls’ that lubricate the two surfaces. As friction is the cause of massive energy waste in various devices, this discovery can be hugely beneficial for saving energy and money in a multitude of fields.

Superlubricity required two perfectly flat surfaces with incompatible crystal structures to slide past each other. It has only been detected in extremely small samples, however, as larger surfaces have imperfections that tend to get stuck as they slide. This is why creating superlubricity in a large sample is so unique.

LFP battery cathode improved by using graphene

Researchers at the Harbin Institute of Technology in China and the University of Michigan in the US demonstrated improved LFP battery cathode, augmented by reduced graphene oxide. The scientists used reduced graphene oxide (rGO) in LFP battery cathodes to create a new high surface area 3D composite.

LFP (or LiFePO4) is a kind of Li-Ion rechargeable battery for high power applications, such as electric vehicls, Power Tools and more. LFP cells feature high discharging current, non explosive nature and long cycle life, but its energy density is lower than normal Li-Ion cell. In this study, the researchers created the composite using a nickel foam template that was coated with layers of graphene oxide. The graphene oxide reduced as the LFP nanoparticles were synthesized in a simple technique that allows larger amounts of the LFP to be loaded into the carbon material.

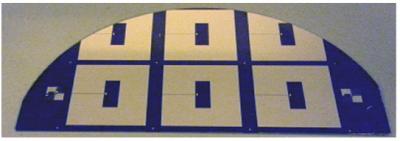

Researchers demonstrate a graphene-based tunable microwave antenna

A European collaboration of scientists from Romania, Greece, Italy, and Ireland demonstrated a graphene antenna that operates in the microwave part of the spectrum and can be tuned by applying a voltage. Graphenea supplied the graphene for this research.

The antenna is less than 1mm thick and has a planar diameter of 100mm, which according to the team makes it one of the smallest microwave antennas in the existence. It was produced using a simple fabrication procedure and a standard CVD graphene layer on an SoI substrate.

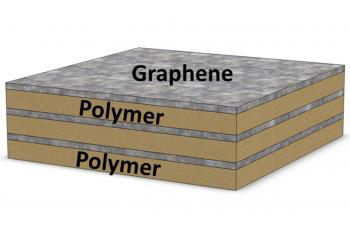

ORNL researchers showcase large-scale graphene production method

Researchers at the US Department of Energy's Oak Ridge National Laboratory (ORNL) came up with an innovative large-scale graphene fabrication method. The scientists used CVD to create 2-inch-by-2-inch sheets of graphene, contained in a polymer composite. Layering graphene between polymer sheets is meant to facilitate use in commercial products, according to the scientists.

Common approaches to polymer composite fabrication use graphene flakes, creating flake dispersion and agglomeration problems. This method, however, uses graphene sheets that eliminate these problems and allow for better electrical conductivity with a lower graphene content in the composite. In fact, the scientists claim that they were able to make a nanocomposite laminate that is electrically conductive with graphene loading that is 50 times less compared to other samples.

Angstron Materials teams with Stryke Industries to accelerate graphene commercialization

Angstron Materials announced that it has teamed with Stryke Industries to accelerate development and commercialization of graphene products for military and defense applications. The US-based business development firm provides a multi-tiered network of resources, designed to promote economies of scale and shorter lead times for bringing new products to market.

Angstron Materials announced that it has teamed with Stryke Industries to accelerate development and commercialization of graphene products for military and defense applications. The US-based business development firm provides a multi-tiered network of resources, designed to promote economies of scale and shorter lead times for bringing new products to market.

Stryke Industries specializes in identifying and implementing disruptive technologies that can help equip military personnel and provide problem-solving solutions for defense industries.

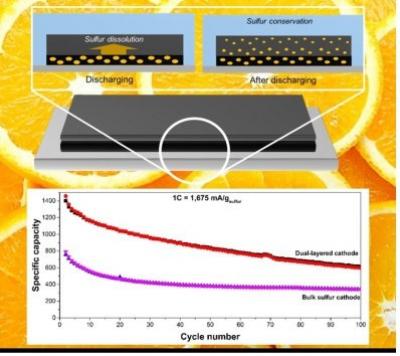

Korean researchers design vitamin c-treated graphene-sulfur cathode for Li-S batteries

Korean researchers at the Gwangju Institute of Science and Technology designed a lithium-sulfur battery with vitamin C treated dual-layered cathode, that achieved a 20% improvement in performance compared to traditional ones.

Lithium-sulfur batteries boast a superior energy density, which is why they are hoped to someday be used in electric vehicles, but disadvantages like poor cycle performance and low charge/discharge rates are still in the way. This study presented a vitamin C treated dual-layered cathode, which is composed of a sulfur active layer and a polysulfide absorption layer, that can increase sulfur utilization dramatically resulting in a lithium-sulfur battery with a high specific capacity of over 600 mAh/g after 100 cycles even under a high current rate of 1C.

Applied Graphene Materials received positive results from oil trials

The UK-based Applied Graphene Materials reports positive preliminary findings following independent performance testing on graphene-enhanced base oils produced by the group. The performance testing was undertaken by BfB Oil Research in Belgium.

The UK-based Applied Graphene Materials reports positive preliminary findings following independent performance testing on graphene-enhanced base oils produced by the group. The performance testing was undertaken by BfB Oil Research in Belgium.

Base oils are used in a many industries, like lubricating greases, motor oils and metal processing fluids. BfB's initial results demonstrate that low loading levels of the group's graphene nanoplatelets, within base oils, reduce friction and the wear of metal surfaces. This opens up the way to further development for commercial applications in high performance oils and greases.

Alabama Graphite reports various graphene derivatives found in its US property

In March 2015, Alabama Graphite announced that it has found naturally occurring flake graphene at its Coosa Property in Alabama, USA. Now, the company declares that it has found additional types of naturally occurring graphene-based derivatives, namely few-layer graphene (2-5 layers), multi-layer graphene (2-10 layers), and graphite nanoplates (less than 100 nm thick) at the same property.

In March 2015, Alabama Graphite announced that it has found naturally occurring flake graphene at its Coosa Property in Alabama, USA. Now, the company declares that it has found additional types of naturally occurring graphene-based derivatives, namely few-layer graphene (2-5 layers), multi-layer graphene (2-10 layers), and graphite nanoplates (less than 100 nm thick) at the same property.

The materials were obtained using the same cost-effective process as was previously used by the Company to obtain graphene. These types of graphene-based derivatives are valued thanks to their unique electrical, optical, mechanical, and thermal properties. The company claims that The graphene-based derivative materials may hold promise for uses in exciting new applications such as thermal management, structures, coatings, power storage, transparent conductive films, conductive inks, structural electronics and sensors.

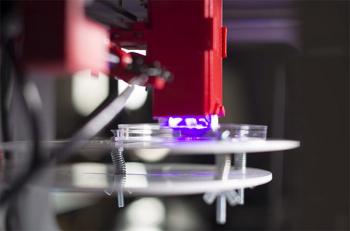

Scientists working toward 3D printing graphene-based functional nerves

Researchers at Michigan Technological University are gaining progress in their work to 3D print replacement nerves using 3D bioprinting techniques. The team has developed polymer materials that can act as a scaffold for growing tissues and is working on integrating graphene as the electrical conductor.

If successful, the combination of the suitable bio-inks, printing technology and conductive graphene may enable the creation of electricity-based medical applications, like functional nerve tissues that can be transplanted into patients.