Talga launches Phase 2 processing plant in Germany

Talga Resources announced the commissioning of its Phase 2 processing plant in Germany, an expansion which will bring about increased capacity for their development of graphene production techniques. While Talga is not yet up to full scale mining at its Vittangi project in Sweden, it has aimed to develop graphite and graphene product specifications and identify applications that will improve the performance of existing industrial materials.

Talga Resources announced the commissioning of its Phase 2 processing plant in Germany, an expansion which will bring about increased capacity for their development of graphene production techniques. While Talga is not yet up to full scale mining at its Vittangi project in Sweden, it has aimed to develop graphite and graphene product specifications and identify applications that will improve the performance of existing industrial materials.

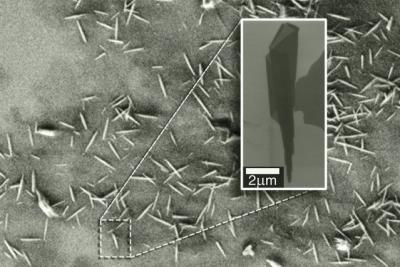

New production cells installed at the Rudolstadt test-work facility have upgraded processing ability from 10kg to 50kg slabs of graphite per cell, with a total ore feed capacity of 365kg. Talga utilizes electrochemical exfoliation to unzip layers of graphite at the atomic level from raw slabs of high grade Vittangi graphite, as well as a proprietary recovery and concentration process.