Haydale and PETRONAS collaborate to accelerate graphene-enhanced commercial applications

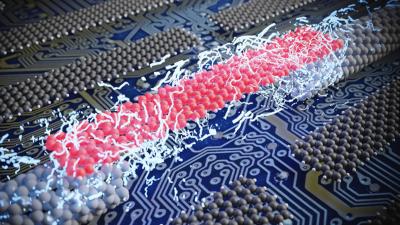

Haydale and PETRONAS Technology Ventures (PTVSB), the technology commercialization arm of Petroliam Nasional Berhad (PETRONAS), have executed a collaboration agreement to functionalize graphene for product applications, in an effort to accelerate commercialization of graphene-based formulations in various different industries.

The agreement, which runs through to 31 December 2025, will see the parties exploring graphene for further commercial applications in battery cells, composites, coatings and thermal materials, among others. The collaboration will also cover knowledge sharing between the parties.