Norway-based CealTech was established in 2012 to commercialize a patented 3D graphene production method. The company recently received its first prototype proprietary industrial-scale Plasma-Enhanced Chemical Vapor Deposition (PE-CVD) graphene production reactor.

Norway-based CealTech was established in 2012 to commercialize a patented 3D graphene production method. The company recently received its first prototype proprietary industrial-scale Plasma-Enhanced Chemical Vapor Deposition (PE-CVD) graphene production reactor.

We discussed CealTech's technology and business with the company's marketing and sales manager, Michel Eid. Michael holds a Ph.D. in Solid Mechanics from the Ecole Polytechnique in France, and held various roles in engineeing, manufacturing, sustaining, sales, marketing and business development. Michel joined CealTech in January 2017.

Q: Hello Michael. CealTech is commercializing a patented 3D graphene production method. Can you give us some details on the process and the material you are producing?

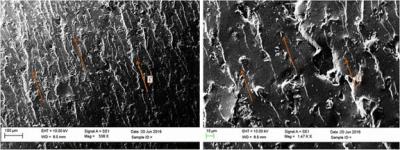

Our production process is based on David Boyd’s technique as per Nature communications (DOI: 10.1038/ncomms7620), ‘Single-step deposition of high-mobility graphene at reduced temperatures’. In summary, the substrate is directly exposed to a low-pressure, microwave hydrogen plasma containing small amounts of methane as carbon source. During this process, vertical grown graphene flakes nucleate and arrange perpendicularly to the surface of the substrate forming a so-called 3D network of non-agglomerated graphene flakes.