An Aerospace Graphene Industry Base to be built in China

The government of Xiangyang, China, has recently signed a strategic cooperation agreement with the Hubei Institute of Aerospace Chemical Technology. Under the agreement, the two sides will jointly build the China Aerospace Graphene Industry Base in Central China.

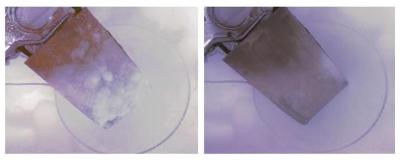

Graphene has many potential applications in the aerospace industry, like strong and durable composites, high-performance sensors, various functional coatings, batteries, supercapacitors and more. Recent examples of progress made in this field include a graphene-based UAV made by UK collaboration, a graphene-enabled composite with potential uses in the automotive and aerospace industries, a collaboration between Versarien and the Spain-based CT Engineering to develop graphene-enhanced composite components for the aerospace industry, a novel coating of graphene nanoribbons in epoxy, that was proven effective at melting ice on a helicopter blade and more. To read more on the latest graphene advances in the aerospace field, click here.